Your Best Partner In Injection Molding

Reliable Mold Maker

Lower The Cost

Spead up your production

Excellect Service Response

Get A free Quote within 1 minute

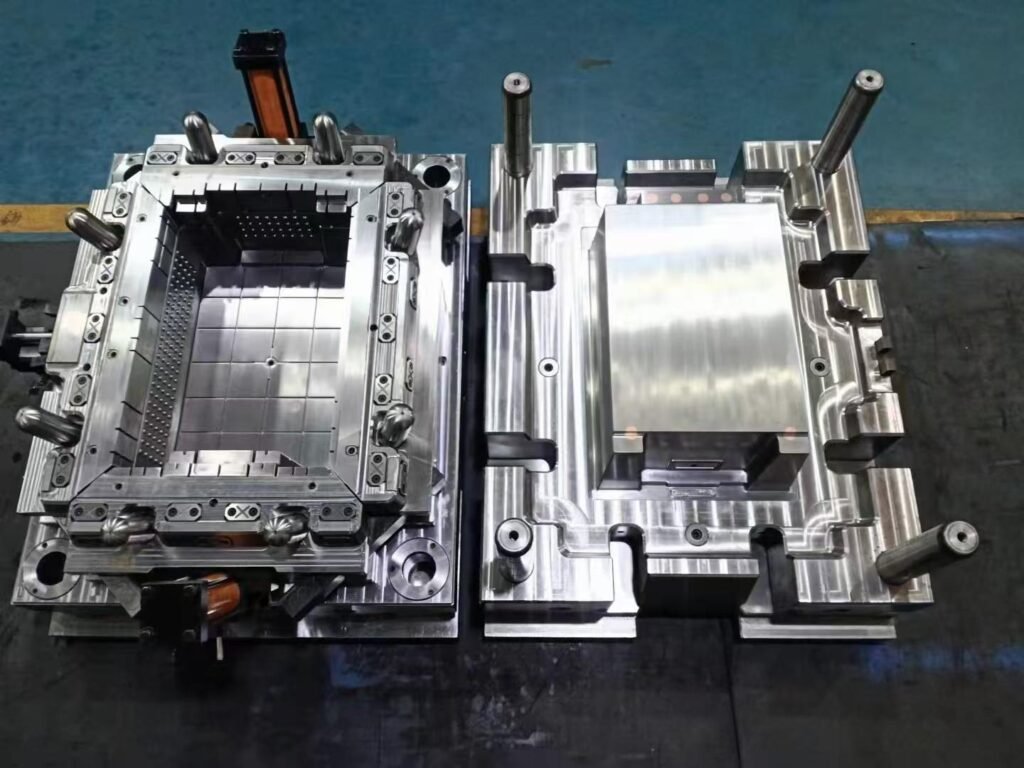

Popper Mold-Tech is A Mold Maker that has been helping customers since 2008. We are based in China and specialize in making high-quality injection molds. Our team has 30 skilled engineers who work hard to create the best molds for your products.

At our injection moulding factory, we use advanced machines and technology to make sure your molds are strong, precise, and built to last. Whether you need a simple mold or a complex one, we have the experience to get it done right.

We work with different materials like plastic and metal to make sure your products come out just the way you want. Our engineers carefully check every step of the process to ensure top quality.

If you’re looking for a reliable Injection Mould Company in China, Popper Mold-Tech is here to help. We take pride in delivering high-quality molds on time and meeting your needs. Trust us to help bring your ideas to life with our expert services!

CAPABILITIES From The Mold Maker

Mold Design

Mold Desig is making the plans for a mold that shapes plastic parts.it involves figuring out how the mold will be made, how the plastic will flow, and how to cool it

Mold Maker

Mold manufacturing is the procoess of making the actual mold from a design. It involes cutting and shaping materials to create a mold that will form plastic parts when the plastic is poured in

Injection Molding

Melted plastic will be push in to a mold to make shapes or parts.After the plastic cools and hardens,It takes the shape of the mold.

3D printing

Building Layer by layer from a digital design.A machine melts or deposit material, like lastic, to create a solid object. It is one of the most important process during R&D before making actual injection mold

Vacuum Molding

Uses a premade mold and vacuum pressure to shap a heated plastic sheet around the mold. It’s faster for making multiple copies of the same part,especially simple shapes.

Why Popper Mold - Tech Be your Mold Maker

1.Precision: We deliver high-quality, accurate molds every time.

2.Customization: Tailored solutions to fit your specific project requirements.

3.Reliability: On-time delivery, ensuring your production schedule stays on track.

4.Innovation: Cutting-edge technology for advanced, efficient solutions.

5.Expertise: Comprehensive support from design through production.

6.Sustainability: Eco-friendly practices and materials to meet your sustainability goals