How Material Selection Impacts Medical Injection Molding

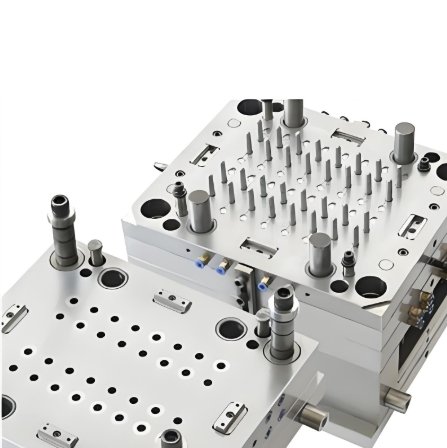

Material selection is a crucial step in medical injection molding. The right material ensures safety, durability, and compliance with regulations. A skilled mold maker plays a key role in selecting the best material for each application. This decision impacts the performance and reliability of medical devices. 1. The Role of Materials in Medical Devices Materials […]

How Material Selection Impacts Medical Injection Molding Read More »