Medical Injection Molding in Diagnostic Equipment Manufacturing

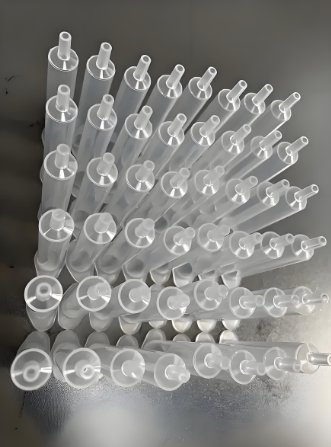

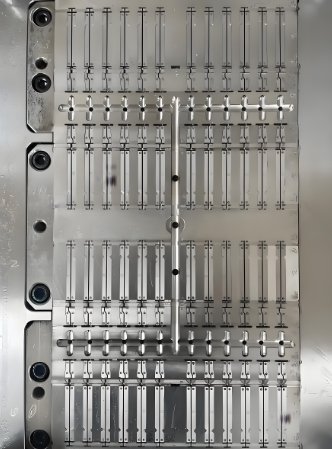

Diagnostic equipment plays a crucial role in healthcare. It helps doctors detect diseases early. Medical injection molding ensures these devices meet high standards. Mold makers create precise components for accuracy and reliability. Why Diagnostic Equipment Needs Injection Molding 1. High Precision Diagnostic tools require exact measurements. Injection molding provides tight tolerances. 2. Durability Medical devices […]

Medical Injection Molding in Diagnostic Equipment Manufacturing Read More »