Injection Molding for IoT Devices and Smart Technology

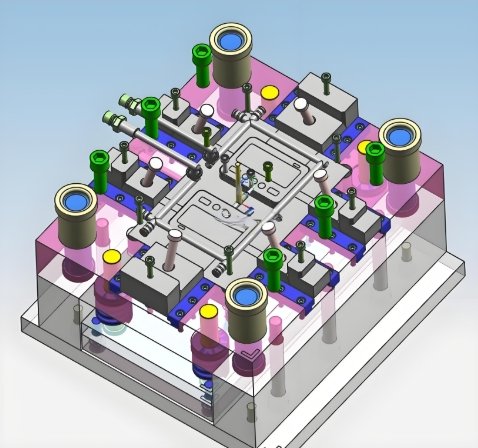

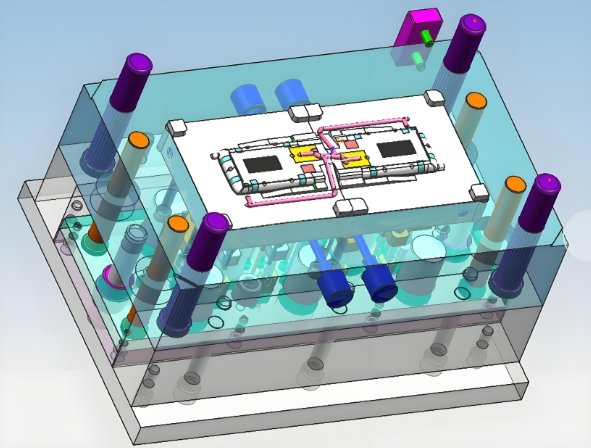

IoT devices are everywhere. Smart homes, healthcare, and industries rely on them. These devices need precision, durability, and lightweight materials. Electronic injection molding is the best method for making them. Mold makers create small, complex parts with high accuracy. 1. Why IoT Devices Need Injection Molding 1.1 Precision for Miniature Components IoT devices have tiny […]

Injection Molding for IoT Devices and Smart Technology Read More »