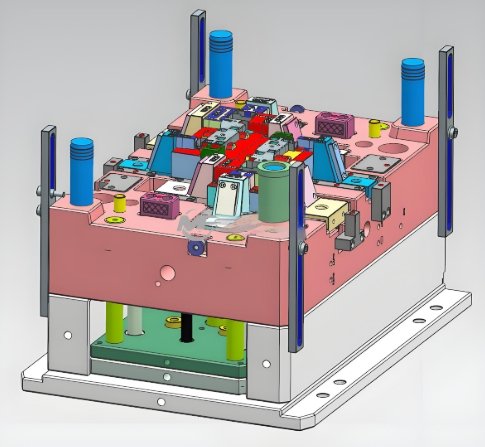

Injection Molding Automation for High-Volume Electronic Parts

Speed matters.Quality matters more.High volume?That’s the challenge. Electronic Injection Molding answers that challenge.With automation, it becomes unstoppable.A skilled Mold Maker builds the tools.Automation does the rest. Let’s explore how it works. Why Automation Is Key Manual labor slows things down.Errors happen.Output drops. Automation makes processes faster.It removes human mistakes.It lowers costs over time.It keeps high-volume […]

Injection Molding Automation for High-Volume Electronic Parts Read More »