Medical & Pharmaceutical

Injection Molding in Medical & Pharmaceutical Industries

Injection molding is crucial in the medical and pharmaceutical industries. It allows for efficient, high-precision production. Therefore, mold maker is the essential. They ensure that molds meet strict standards.

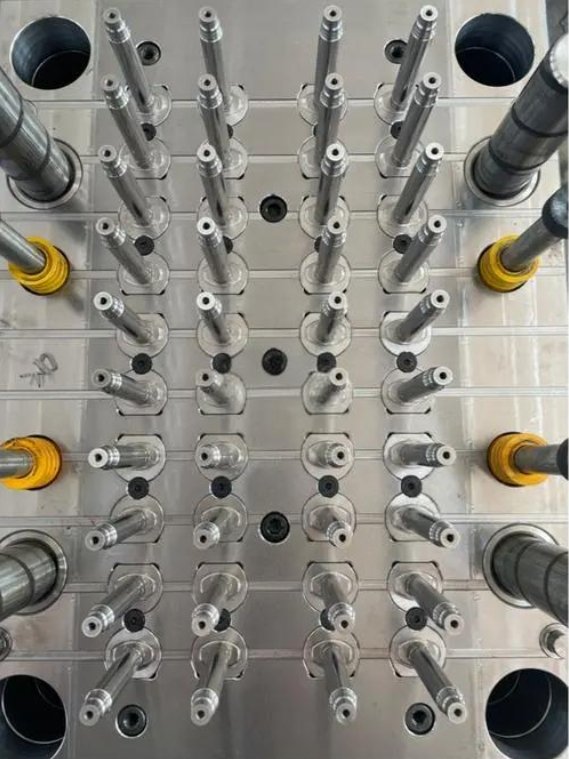

Syringes - Tips from the Mold Maker

Injection molding produces syringes with high precision and sterility. Therefore, focus on precise tolerances. This accuracy is vital for correct dosage delivery.

Caps and Closures

Caps and closures for bottles and vials rely on injection molding. Thus, mold design with tight seals. This process helps prevent contamination and ensures safety.

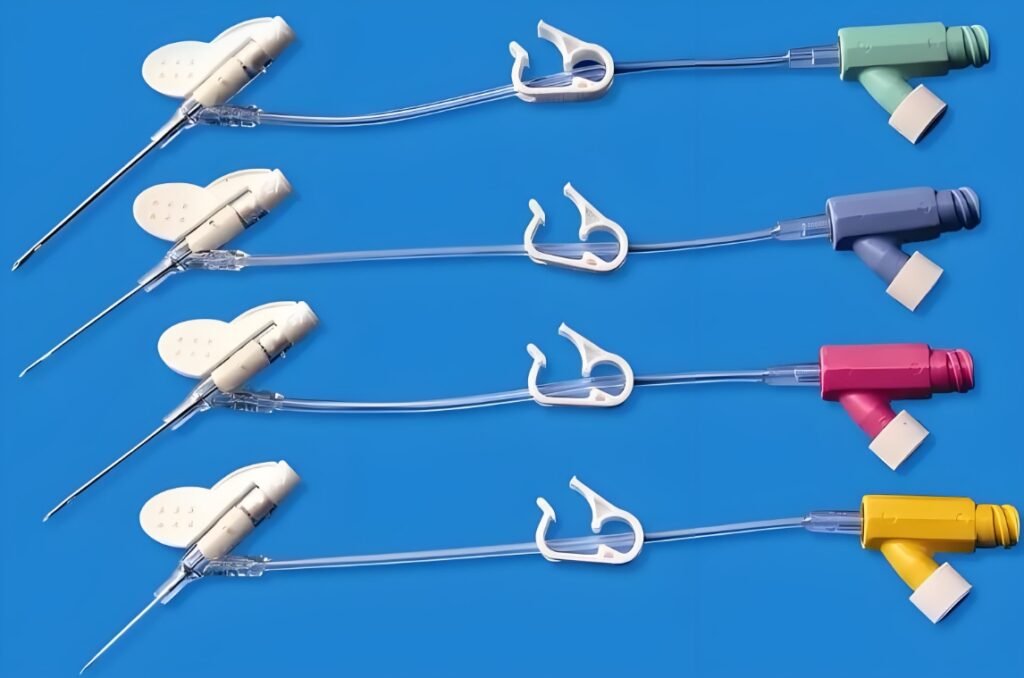

Catheters and Tubes - Tips from the Mold Maker

Catheters and tubes need to be thin, flexible, and durable. For this reason, Injection Mould Company create molds that meet these requirements. As a result, injection molding ensures consistent wall thickness, which is crucial for medical use.

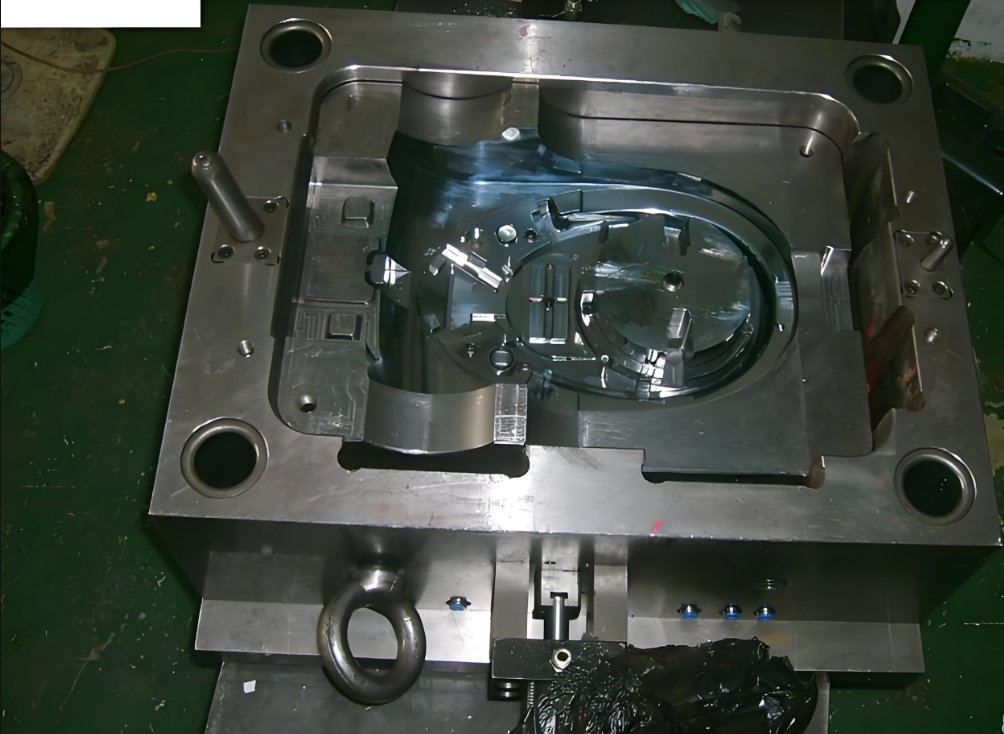

Inhaler Components - Insights from the Mold Maker

Inhalers require precise parts to function properly. So, A good mold design that guarantee this precision. Consequently, injection molding delivers consistent, reliable production.

Advantages of Injection Molding in These Sectors

Precision and Accuracy:Injection molding provides exact measurements. This precision is critical in medical applications, where errors can be life-threatening.

High Production Volume:Mold makers enable mass production through their molds. Therefore, injection molding easily meets the high demand in these industries.

Material Versatility: Medical-grade plastics are versatile and necessary. So, Injection Mould company selects materials that are both biocompatible and sterilizable.

Cost-Efficiency: Once a mold is created, the cost per part decreases. This efficiency makes injection molding ideal for producing disposable medical items.

Consistency and Quality Control: In conclusion, injection molding is essential in medical and pharmaceutical sectors. Thanks to the injection Mould Company, the process meets all strict industry requirements.

Injection molding is essential in medical and pharmaceutical sectors. Because of good injection mould company, the process meets strict industry requirements.