Aerospace manufacturing demands precision and efficiency. Every part must meet strict quality standards. Injection molding is a key process used to create components for this industry. Behind this process is the mold maker. They design and create injection molds that help streamline production.

In this article, we will explore the vital role of mold makers in aerospace manufacturing. We will examine how their expertise contributes to better production efficiency, reduced costs, and high-quality parts.

The Role of Injection Molding in Aerospace Manufacturing

Injection molding is a method used to produce parts by injecting molten material into a mold. In aerospace, this process is ideal for producing lightweight and complex parts. Aircraft components need to be both strong and light. The ability to mold parts with tight tolerances makes injection molding perfect for aerospace applications.

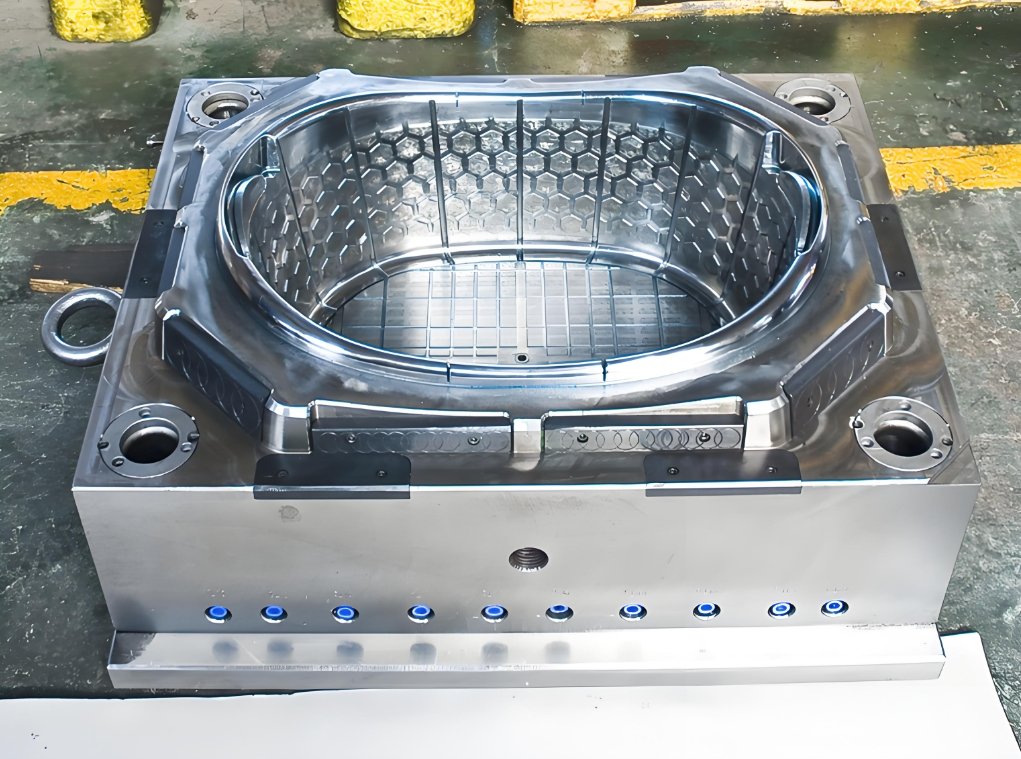

Injection molds used in aerospace must be durable and precise. This is where the mold maker comes in. They design injection molds that meet the specific requirements of each part. These molds can withstand the high pressures and temperatures involved in the injection molding process.

How Mold Makers Support Aerospace Manufacturing

Mold makers play an essential role in aerospace manufacturing. Their job is to create molds that meet strict design specifications. Injection molding in the aerospace industry requires accuracy. Even the smallest error can affect a part’s performance.

A mold maker uses advanced design tools to create custom molds. They ensure that each mold can produce parts with consistent quality. Mold makers also use simulations to test their designs before manufacturing begins. This helps them identify potential problems early on.

Custom Injection Molds for Aerospace Parts

Every part in aerospace manufacturing is unique. Custom injection molds are required for each specific part. Mold makers work with engineers to create molds that fit the design specifications exactly. This ensures that each part produced is a perfect match.

Mold makers take many factors into account when designing custom injection molds. They consider the material, part geometry, and production requirements. For aerospace parts, the mold must allow for complex shapes and precise features.

Using custom injection molds allows manufacturers to produce parts quickly and accurately. This improves production efficiency while maintaining high-quality standards.

Reducing Production Time with Efficient Mold Design

One of the most significant contributions of a mold maker is improving production efficiency. Injection molds designed for aerospace must optimize the production process. A well-designed mold can reduce cycle times, allowing manufacturers to produce more parts in less time.

Efficient mold design also helps minimize defects. A mold maker ensures that the mold is built to exact specifications, reducing the chances of part defects during production. This results in fewer rejected parts and less wasted material.

By reducing production time and minimizing defects, a mold maker helps aerospace companies meet their production goals faster.

Cost Savings through Precise Mold Design

A mold maker’s expertise in creating precise injection molds leads to cost savings. In aerospace manufacturing, materials can be expensive. By designing molds that minimize waste, a mold maker helps reduce material costs.

Additionally, high-quality injection molds ensure that parts are produced with fewer defects. This reduces the need for rework or part replacement, saving both time and money.

The initial investment in custom injection molds may seem high. However, the long-term savings in reduced material waste and improved production efficiency outweigh the upfront costs. Mold makers are key to achieving these cost savings.

Quality Control in Aerospace Injection Molding

Quality control is critical in aerospace manufacturing. Each part must meet exacting standards to ensure safe and efficient operation. Injection molding in aerospace relies on molds that produce parts with tight tolerances and flawless surfaces.

Mold makers ensure that their molds meet strict quality standards. They conduct thorough testing during the mold design and manufacturing process. This includes using computer simulations to test the mold’s performance and making necessary adjustments.

Once the mold is complete, mold makers perform detailed inspections to ensure it meets the required specifications. This attention to quality ensures that the injection molds produce parts that meet aerospace standards.

Collaboration between Mold Makers and Injection Mould Companies

A mold maker often collaborates closely with an injection mould company. This partnership ensures that the mold design aligns with the company’s production needs. The mold maker provides technical expertise to create a mold that meets the company’s requirements.

In aerospace manufacturing, the injection mould company depends on the mold maker to deliver high-quality molds. These molds must be designed to handle the unique challenges of aerospace parts. The collaboration between the mold maker and the injection mould company results in better outcomes for the client.

Challenges Faced by Mold Makers in Aerospace Manufacturing

Mold makers face several challenges in the aerospace industry. The first is the complexity of the parts. Aerospace components often have intricate designs and complex geometries. Creating injection molds that can handle these parts requires advanced skills and technology.

Another challenge is the need for lightweight materials. Aerospace parts must be light but strong. This requires mold makers to work with specialized materials that can withstand high pressures and temperatures.

Despite these challenges, mold makers continue to play a vital role in aerospace manufacturing. Their ability to create custom injection molds ensures that the industry can meet its precision and quality requirements.

In aerospace manufacturing, precision and efficiency are essential. Injection molding is a key process for producing parts that meet these requirements. Mold makers play a critical role in this process. Their expertise in creating custom injection molds ensures that aerospace companies can produce high-quality parts quickly and efficiently.

By reducing production time, minimizing defects, and controlling costs, mold makers help streamline aerospace manufacturing. Their attention to detail and commitment to quality make them indispensable partners in the industry.

As aerospace continues to evolve, the role of the mold maker will become even more important. Companies that invest in skilled mold makers will benefit from better production outcomes and a stronger competitive edge.