Injection Molding has become a critical process in the manufacturing of medical devices. From small components to large assemblies, the ability to produce precise, high-quality parts is essential. Injection Molds are used to create parts that meet strict medical industry standards. Partnering with an experienced Injection Mould Company ensures the highest quality and reliability in medical device production.

What is Injection Molding in Medical Device Manufacturing?

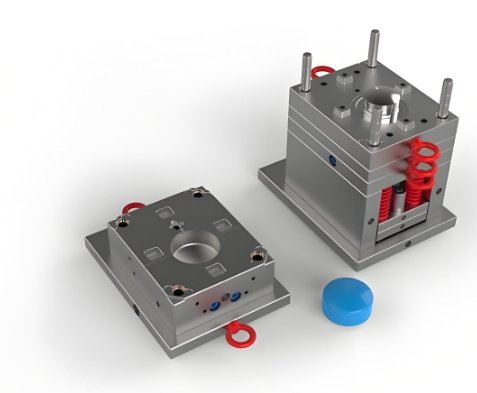

Injection Molding is a manufacturing process where molten material is injected into a mold cavity to produce parts. This method is widely used in producing plastic components for medical devices. The precision and consistency of Injection Molding make it ideal for the medical industry, where quality and safety are paramount.

For medical devices, Injection Molding allows for the production of small, complex, and intricate parts. Whether it’s surgical instruments, diagnostic tools, or components for drug delivery systems, Injection Molds are integral to ensuring these devices meet rigorous standards.

The Role of a Mold Maker in Medical Device Manufacturing

A skilled Mold Maker plays a crucial role in the production of high-quality Injection Molds. The Mold Maker is responsible for designing, creating, and maintaining the molds that will be used in Injection Molding. In the medical device industry, these molds must meet tight tolerances and be made from materials that are durable and biocompatible.

Working with an experienced Mold Maker ensures that the molds are precisely manufactured to meet the required specifications. A small error in the mold can lead to defects in the final product, which can be costly and even dangerous in the medical field. Therefore, choosing the right Injection Mould Company with expert Mold Makers is essential.

Benefits of Using an Injection Mould Company for Medical Devices

- Precision and Consistency One of the primary advantages of using an Injection Mould Company for medical device manufacturing is the precision and consistency it offers. Injection Molding allows for the production of thousands of identical parts with little to no variation. This level of consistency is essential for medical devices, where even minor defects can compromise functionality and safety.

- Speed and Efficiency Injection Molding is a fast process, especially when compared to other manufacturing methods. Once the Injection Molds are created, production can begin immediately, and large quantities of parts can be produced in a short time. This speed is beneficial in the medical industry, where time-to-market can be crucial for the success of a new device.

- Cost-Effectiveness While the initial cost of creating Injection Molds may be high, the overall cost of production can be lower than other methods. Once the molds are made, parts can be produced quickly and in large quantities, reducing the overall cost per part. This cost-effectiveness is important for medical device manufacturers looking to produce high-quality products at competitive prices.

- Material Versatility Another benefit of Injection Molding is the ability to work with a wide variety of materials. In medical device manufacturing, materials must meet specific requirements, such as biocompatibility, durability, and chemical resistance. An Injection Mould Company with a wide range of material options can help ensure the correct material is used for each device part.

- Complex Geometries Medical devices often require parts with intricate shapes and designs. Injection Molding is perfect for producing complex geometries that other manufacturing methods cannot achieve as efficiently. This allows for the creation of medical device components with fine details, sharp corners, and other challenging features.

The Injection Molding Process for Medical Devices

The process of Injection Molding in medical device manufacturing involves several key steps:

- Design and Prototyping The first step is designing the part. A skilled Mold Maker works with engineers to create a 3D design of the component. This design is then used to create a prototype. Prototypes are essential in testing the functionality and fit of the part before mass production.

- Mold Creation Once the design is finalized, the next step is creating the mold. The Mold Maker uses precision tools and equipment to create molds that will accurately shape the final product. For medical devices, this step requires high attention to detail to ensure that the mold meets all necessary medical and regulatory standards.

- Injection Molding After the mold is created, the Injection Molding process begins. The chosen material, typically plastic, is heated until it becomes molten. This molten material is then injected into the mold cavity under high pressure. Once the material cools and hardens, the part is ejected from the mold.

- Quality Control In the medical device industry, quality control is critical. Every part must be inspected to ensure it meets the strict standards required. This includes checking for defects, consistency, and precision. A reliable Injection Mould Company will have a robust quality control system in place to ensure every part meets medical standards.

- Post-Processing Some medical device parts may require post-processing after the Injection Molding process. This can include trimming, polishing, or adding additional features such as assembly. Post-processing ensures that the final product is ready for use and meets all medical requirements.

Choosing the Right Injection Mould Company

When selecting an Injection Mould Company for medical device manufacturing, it’s important to consider several factors:

- Experience in Medical Devices The company should have experience in producing medical device components. This ensures that they understand the unique challenges and requirements of the industry.

- Expertise in Injection Molding The company should specialize in Injection Molding and have a proven track record of producing high-quality molds and parts. Expertise in Injection Molds is essential for ensuring the accuracy and functionality of the components.

- Regulatory Knowledge Medical devices are subject to strict regulatory standards, such as FDA approval and ISO certification. The right Injection Mould Company should have a deep understanding of these regulations and ensure that all parts produced meet the necessary requirements.

- Proven Quality Control Quality control is essential in the medical device industry. Look for a company that has a proven quality control process to ensure that every part meets the highest standards.

Injection Molding plays a vital role in the manufacturing of medical devices. By working with a skilled Mold Maker and an experienced Injection Mould Company, manufacturers can ensure the production of high-quality, precise parts that meet strict medical standards. From fast production times to cost-effective solutions, Injection Molding offers several advantages for the medical device industry. Choosing the right company is crucial to ensuring that these benefits are fully realized.