Injection mould companies provide a wide range of services to meet the needs of various industries. These services focus on creating high-quality products with precision and efficiency. The injection molding process is key to producing durable and cost-effective items. Here, we will explore the top five services that injection mould companies offer to their clients.

1. Injection Molding for Mass Production

Injection molding is one of the core services provided by injection mould companies. This service involves injecting molten material into a mold to form a specific product. It is a highly efficient method, especially for mass production. Whether you need thousands or millions of identical parts, injection molding is the ideal solution.

The process offers high precision and repeatability. Once the mold is created, parts can be produced in large quantities with consistent quality. The use of advanced technologies and machines ensures that the process runs smoothly. In addition, injection molding can be used with a variety of materials, such as plastics, metals, and even silicone.

2. Custom Mold Maker Services

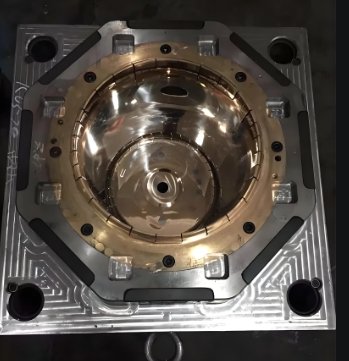

One of the most important aspects of injection mould companies is their mold maker services. Mold makers are highly skilled professionals who design and create custom molds tailored to the client’s needs. This service is crucial when producing complex parts with unique shapes or when you need high precision.

Custom molds are made using advanced CAD (Computer-Aided Design) software. This allows mold makers to create detailed and accurate designs before the mold is physically produced. The mold maker ensures that the mold is designed to withstand the pressures and heat of the injection molding process, allowing for consistent production of parts without defects.

3. Prototype Development

Before mass production begins, many injection mould companies offer prototype development services. Prototypes are essential for testing the design, functionality, and overall quality of a product before investing in large-scale production. Injection molding is used to create prototypes quickly and cost-effectively.

This service helps clients identify any design flaws or issues with the product. It is also useful for ensuring that the product meets safety standards and customer expectations. Prototype development allows for adjustments and improvements before committing to the final product.

4. Mold Maintenance and Repair

Molds, especially those used in injection molding, require regular maintenance to ensure they continue to function properly. Injection mould companies offer mold maintenance and repair services to keep the molds in excellent condition. Over time, molds can become worn or damaged, which may affect the quality of the parts being produced.

Regular inspection and maintenance help prevent these issues. Injection mould companies will perform routine checks to ensure that the mold is operating correctly and producing parts with the desired specifications. In addition, when molds become damaged or worn, companies offer repair services to restore them to full functionality. This service extends the life of the mold, improving overall efficiency.

5. High-Volume Manufacturing Support

High-volume manufacturing is another important service offered by injection mould companies. Once the molds are created and tested, they can be used for large-scale production. This is particularly important for industries that require a consistent supply of products at a fast pace, such as automotive, electronics, and consumer goods.

Injection molding allows for high-volume production with minimal labor and waste. The automated nature of the process ensures that each part is identical, reducing the chance of human error. This is a key benefit for clients who need to maintain high output levels while keeping costs down.

Injection mould companies can help businesses scale their production by providing the necessary tools, expertise, and technology. Whether it’s for producing thousands of parts per day or producing parts in multiple shifts, these companies ensure that production runs smoothly and efficiently.

Why Choose an Injection Mould Company?

Injection mould companies offer a wide range of services designed to meet the specific needs of each client. Whether you require mass production, custom molds, prototypes, or maintenance, these companies provide the expertise and resources needed to deliver high-quality results. Working with a professional mold maker ensures that your product is made with precision and care.

Benefits of Injection Molding

- Cost Efficiency

Injection molding is cost-effective for mass production. Once the mold is created, the cost per part is relatively low. This makes it ideal for producing large volumes of parts while keeping costs under control. - High Precision

The process of injection molding allows for the creation of complex parts with tight tolerances. This is important in industries where precision is critical, such as electronics and automotive. - Material Versatility

Injection molding can be used with a variety of materials, including thermoplastics, metals, and elastomers. This versatility allows manufacturers to produce a wide range of products. - Scalability

Once a mold is created, it can be used for high-volume production. This makes injection molding ideal for scaling production to meet market demand. - Reduced Waste

The automated nature of injection molding reduces material waste, making the process more environmentally friendly and cost-efficient.

Conclusion

Injection mould companies provide valuable services to industries that require high-volume, high-quality production. From injection molding to custom mold maker services, they offer solutions that ensure products are made efficiently and to the highest standards. These companies play a vital role in the production process, helping businesses create durable, cost-effective products with precision.

Whether you’re looking for a partner for prototype development, mass production, or mold maintenance, injection mould companies offer the expertise and technology needed to bring your products to life. Working with a professional mold maker ensures that your molds are made to the highest standards, resulting in consistent, high-quality production.