Manufacturing today demands both quality and affordability. An experienced injection mould company offers cost-effective solutions. They combine precision and efficiency to meet production goals. Through Injection Molding, businesses achieve reliable, affordable results.

How Injection Molding Reduces Costs

Injection Molding minimizes waste. The process uses precise amounts of material. Every shot produces consistent parts. This reduces scrap and saves money. High automation also lowers labor costs. Once a machine is set up, it runs with minimal supervision.

Durable Injection Molds Save Money

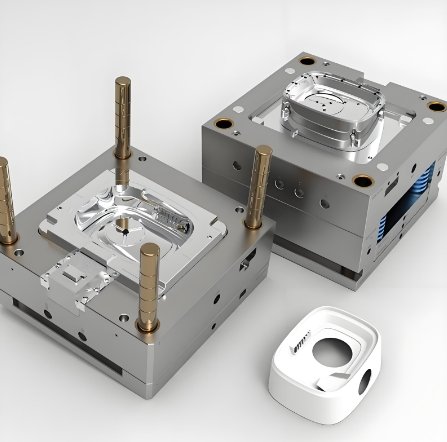

Quality Injection Molds are key to cost efficiency. A skilled Mold Maker creates durable molds. These molds last through thousands of production cycles. Fewer replacements mean lower long-term costs. Investing in high-quality molds pays off.

Mass Production for Economy of Scale

Injection Molding excels in high-volume production. An injection mould company delivers large quantities quickly. The more parts produced, the lower the cost per unit. Businesses save money while maintaining quality.

Material Efficiency in Manufacturing

Material choice affects cost. An injection mould company selects the right plastic for each project. They balance quality with affordability. Advanced Injection Molds use materials efficiently. This minimizes waste and keeps costs under control.

Automation Brings Consistency and Savings

Automation streamlines production. Modern Injection Molding machines produce identical parts every time. This reduces errors and rework. Automation also lowers labor expenses. An injection mould company passes these savings to clients.

Faster Production Means Lower Costs

Time is money in manufacturing. Injection Molding delivers faster production rates. Short cycle times allow for quick order fulfillment. An injection mould company optimizes setup times to meet tight deadlines. Faster production reduces overall expenses.

Low Maintenance Costs with Quality Molds

Well-made Injection Molds require minimal maintenance. A professional Mold Maker ensures molds are durable and reliable. Fewer breakdowns mean fewer disruptions. This stability helps keep manufacturing costs low.

Flexible Solutions for Various Budgets

An injection mould company works with different budgets. They offer flexible services to meet client needs. From small batches to mass production, they provide cost-efficient options. Custom molds fit both technical and financial requirements.

Prototyping Saves Development Costs

Prototyping reduces risks. An injection mould company offers prototype services. This allows businesses to test designs before full production. Catching issues early saves time and money. Prototypes ensure final products meet expectations.

Energy Efficiency in Modern Injection Molding

Energy use impacts manufacturing costs. Modern Injection Molding machines are energy-efficient. They consume less power while maintaining output. This reduces operational costs for the injection mould company. Clients benefit from lower production expenses.

Why Work with an Experienced Mold Maker

A skilled Mold Maker ensures quality and efficiency. Their expertise leads to precise Injection Molds. High-quality molds improve production speed and reduce waste. Choosing the right Mold Maker is crucial for cost-effective manufacturing.

Global Sourcing for Competitive Pricing

Many companies outsource to an injection mould company abroad. Countries like China offer competitive pricing. These companies balance affordability with quality. Businesses save on production costs while meeting industry standards.

An injection mould company ensures cost efficiency at every step. From durable Injection Molds to automated Injection Molding, they deliver value. Working with a skilled Mold Maker helps businesses achieve affordable, high-quality production. Choose a partner that balances quality, speed, and cost.