Sustainability is critical today. Businesses seek ways to reduce waste and lower costs. An experienced Injection Mould Company can help. They use Injection Molding to streamline production and minimize waste.

What Is Injection Molding?

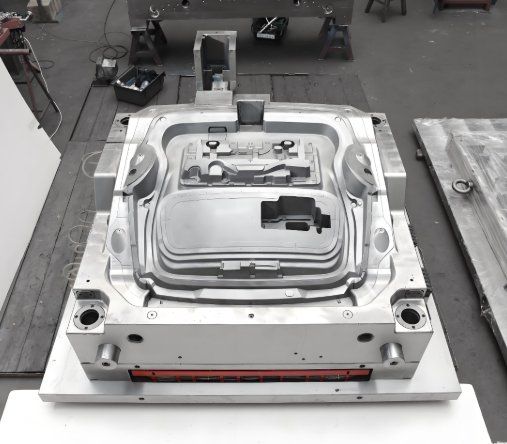

Injection Molding is a precise manufacturing process. It involves injecting material, like plastic, into molds. The result is consistent, high-quality parts.

This process is efficient and eco-friendly. Waste is reduced at every stage.

How Injection Mould Companies Reduce Waste

An Injection Mould Company uses advanced techniques to cut waste. Key methods include:

- Optimized Mold Design

A skilled Mold Maker designs molds that minimize excess material. Proper design ensures efficiency. - Recycling Material

Leftover material is often recycled. This reduces waste and saves costs. - Precision in Production

Injection Molding ensures minimal errors. Accurate molds mean fewer defective parts. - Energy Efficiency

Modern machines consume less energy. This supports sustainable production.

Role of Mold Makers

A Mold Maker is essential in waste reduction. They design and create molds for efficient production.

Key contributions of a Mold Maker include:

- Accurate designs for minimal material use.

- Durable molds that last for multiple production cycles.

- Custom solutions to meet specific requirements.

Without a skilled Mold Maker, reducing waste would be impossible.

Benefits of Injection Molding in Waste Reduction

Injection Molding offers several advantages:

- Minimal Scrap: Precise molds ensure less excess material.

- Reuse of Leftovers: Scraps are repurposed into new parts.

- Efficient Production: Large volumes are produced with little waste.

For businesses, this means lower costs and a smaller environmental impact.

Sustainable Materials

An Injection Mould Company can work with sustainable materials. Options include:

- Biodegradable plastics.

- Recyclable polymers.

- Lightweight, eco-friendly composites.

Using these materials reduces waste further.

Industries Benefiting from Waste Reduction

Many industries benefit from reduced waste in Injection Molding:

- Automotive: Lightweight, efficient parts are essential.

- Consumer Goods: Durable, sustainable products appeal to buyers.

- Medical: Precise components reduce material waste.

- Packaging: Eco-friendly designs cut down on waste.

Each industry relies on an Injection Mould Company for sustainable solutions.

Advanced Technologies in Injection Molding

New technologies make Injection Molding even more efficient. These include:

- Computer-Aided Design (CAD)

Molds are designed with precision. Waste is reduced from the start. - Hot Runner Systems

These systems eliminate excess material in production. - Automation

Automated processes reduce errors. This minimizes defective parts.

An Injection Mould Company uses these technologies to lead in waste reduction.

Economic Benefits of Waste Reduction

Reducing waste is not just good for the environment. It saves money too. Companies see lower production costs. They also improve efficiency.

Partnering with a trusted Injection Mould Company ensures long-term savings.

Steps to Choose the Right Injection Mould Company

Selecting the right partner is crucial. Look for:

- Expertise in Injection Molding.

- Skilled Mold Makers.

- Proven success in reducing waste.

- Use of sustainable materials and technologies.

An experienced company will meet these standards.

The Future of Waste Reduction

The future is focused on sustainability. Injection Molding will continue to evolve. Trends include:

- Increased use of recycled materials.

- Smarter mold designs for efficiency.

- Enhanced automation to reduce errors.

An innovative Injection Mould Company stays ahead of these trends.

Reducing waste is essential in modern production. An Injection Mould Company plays a key role. Using advanced Injection Molding, skilled Mold Makers, and custom Injection Molds, they deliver efficient, eco-friendly solutions.

Partnering with the right company ensures sustainable success. Lower costs, reduce waste, and improve production quality with expert help. Choose an Injection Mould Company today for a greener tomorrow.