The construction industry requires durable, reliable, and cost-effective components. Injection Molding provides an excellent solution for creating high-quality parts that meet these demands. By working with a skilled Injection Mould Company, businesses in the construction sector can access the best possible solutions for their needs. Injection Molds and experienced Mold Makers are at the heart of this process, delivering precision and consistency.

What Is Injection Molding?

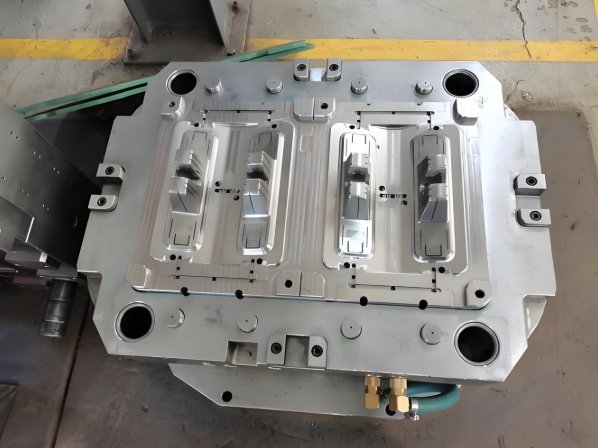

Injection Molding is a manufacturing process that involves injecting material into a mold to create parts. The material can be plastic, metal, or other substances. This method is highly efficient, especially for mass production. Injection Molds are designed to create specific shapes, ensuring uniformity and precision. In construction, this process is used to produce a wide range of parts, from small components to large structural elements.

Role of an Injection Mould Company

An Injection Mould Company provides everything needed for Injection Molding production. This includes the design and creation of molds, the selection of materials, and the actual production of parts. Injection Molding is a key part of many industries, but it is particularly beneficial for construction. The durability, cost-effectiveness, and speed of production make it a preferred method.

Benefits of Using an Injection Mould Company in Construction

The construction industry involves a range of needs, from building interiors to heavy-duty materials for exteriors. An Injection Mould Company can meet all these needs. Here are some key benefits:

- Durability: The Injection Molding process creates parts that are durable and can withstand harsh conditions. These parts are ideal for construction, where components must endure wear and weather over time.

- Customization: An experienced Mold Maker can design molds to create parts that meet specific construction needs. Whether you need complex shapes or custom features, Injection Molding can deliver.

- Efficiency: Injection Molding is a fast process, making it ideal for the construction industry, where time is often critical. Parts can be produced quickly and in high volumes, ensuring that projects stay on schedule.

- Cost-Effective: Once a mold is made, it can be used to produce thousands of parts, reducing the cost per part. This makes Injection Molding a cost-effective choice for large-scale production in construction.

The Importance of Mold Makers

A Mold Maker plays a critical role in the Injection Molding process. The Mold Maker is responsible for designing and creating the molds used in the production of parts. These molds must be precise and durable to ensure the parts produced are of high quality.

For the construction industry, the design of the mold is particularly important. Construction components must meet strict standards for strength, safety, and performance. A skilled Mold Maker will ensure that the mold is designed to handle these demands. They will also ensure that the mold is compatible with the materials used in the Injection Molding process, whether that’s plastic, metal, or another substance.

Types of Injection Molds Used in Construction

There are several types of Injection Molds used in the construction industry. These molds can create a variety of parts for different applications. Here are some examples:

- Plastic Molds: These molds are commonly used for parts like pipes, fittings, and electrical enclosures. Plastic Injection Molds are versatile and can be used to create components with complex shapes.

- Metal Molds: Metal Injection Molds are used for parts that require greater strength, such as structural elements. Steel and aluminum molds are common, as they can withstand high temperatures and stress.

- Custom Molds: Injection Molding allows for the creation of custom parts. Whether you need specific sizes, shapes, or features, a Mold Maker can design a custom mold to meet those needs.

Materials Used in Injection Molding for Construction

The material used in Injection Molding has a significant impact on the performance of the final part. In construction, materials must be chosen for their strength, durability, and resistance to wear and weathering. Here are some common materials used in Injection Molding for construction:

- Plastics: Plastics like ABS, polycarbonate, and PVC are commonly used for construction components. These materials are lightweight, durable, and resistant to corrosion and wear. They are ideal for pipes, fittings, electrical enclosures, and other construction parts.

- Metals: Metals like steel and aluminum are used for parts that need to withstand high stress or high temperatures. Metal Injection Molds are commonly used for structural elements, heavy machinery parts, and other high-performance components.

- Composites: Composite materials are sometimes used in Injection Molding for construction parts. These materials are a blend of plastic and other substances, offering unique benefits like strength, flexibility, and resistance to impact.

How Injection Molding Helps in Construction

Injection Molding is widely used in construction because of its ability to create high-quality, durable parts quickly and cost-effectively. Here are some examples of how Injection Molding benefits the construction industry:

- Plumbing Fittings: Injection Molding is used to create various plumbing fittings, such as joints, elbows, and connectors. These parts are often made from plastic, which is resistant to corrosion and can handle high water pressure.

- Electrical Enclosures: Injection Molding is also used to create electrical enclosures. These enclosures protect electrical equipment from dust, moisture, and physical damage. The molds are designed to create parts that meet safety standards and ensure proper function.

- Building Materials: Injection Molding is used to produce components for building structures, such as window frames, door frames, and other parts that must fit precisely into the construction. These parts must be strong and durable to withstand the elements.

- Insulation Components: Insulation parts for the construction industry can be made using Injection Molding. These parts help to regulate temperature and provide energy efficiency for buildings.

Quality Control in Injection Molding

For the construction industry, quality control is crucial. Parts must meet strict standards for strength, durability, and safety. An Injection Mould Company should have quality control processes in place to ensure that every part produced meets these standards.

The Mold Maker should test the mold for accuracy before production begins. During the production process, the company should inspect parts regularly to ensure they meet specifications. If there are any defects, the company can adjust the mold or materials as needed to correct the issue.

Fast Turnaround Times for Construction Projects

In the construction industry, time is often a critical factor. Delays in receiving the right parts can push back project timelines. Injection Molding provides fast production, helping construction projects stay on schedule. Once the mold is created, parts can be produced quickly and efficiently, reducing lead times.

This fast turnaround is essential for large-scale construction projects where parts are needed in high volumes. Whether you are building a skyscraper or a residential home, Injection Molding can provide the components you need, when you need them.

An Injection Mould Company offers valuable solutions to the construction industry. Through Injection Molding, skilled Mold Makers, and precision Injection Molds, construction companies can access durable, cost-effective components that meet strict performance standards. From plumbing fittings to building materials, Injection Molding plays a critical role in the success of construction projects.

By partnering with a reliable Injection Mould Company, businesses in the construction industry can ensure that they receive high-quality parts that are produced efficiently and to exact specifications. The versatility, speed, and precision of Injection Molding make it an ideal solution for the demands of modern construction.