A strong mold base is essential in Injection Molding. It supports the entire mold structure. An Injection Mould Company specializes in making durable mold bases. Skilled Mold Makers ensure high precision. This guarantees consistent performance.

What Are Mold Bases?

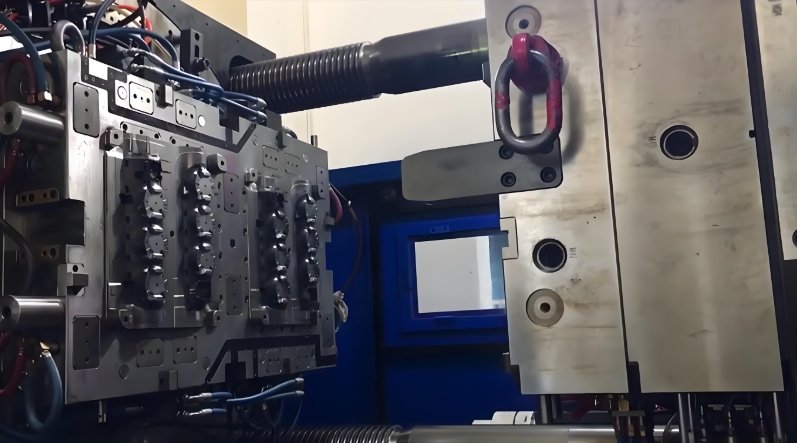

Mold bases are the foundation of Injection Molds. They hold cavities and cores in place. They also align the mold during production. Without a solid base, molds fail. That’s why quality matters.

Importance of High-Quality Mold Bases

- Strength and Durability

Mold bases handle pressure during molding. Weak bases lead to defects. - Precision

Accurate bases ensure alignment. Misaligned molds create defective parts. - Longevity

Good materials extend base life. This reduces replacement costs.

How Injection Mould Companies Make Mold Bases

- Material Selection

Quality starts with materials. Steel is a popular choice. It resists wear and handles stress. - Precision Machining

CNC machines create exact dimensions. This ensures perfect fits. - Heat Treatment

Heat treatment strengthens materials. It improves durability. - Inspection

Every base undergoes strict checks. This ensures flawless performance.

Role of Mold Makers in Mold Base Production

A skilled Mold Maker is crucial. They understand mold design. They know how bases support molds. Their expertise ensures high-quality results. Without them, bases would fail under pressure.

Challenges in Making Mold Bases

- Material Costs

High-quality materials are expensive. Companies must balance cost and performance. - Complex Designs

Some molds need intricate bases. This requires advanced machining. - Precision Requirements

Minor errors cause major problems. Companies invest heavily in precision tools. - Time Constraints

Clients demand quick turnarounds. Companies must streamline processes.

Innovations in Mold Base Production

- Advanced CNC Machines

These create bases with extreme accuracy. - Automated Systems

Robots speed up machining. They also reduce human errors. - New Materials

Companies explore lightweight yet durable materials. - Sustainable Practices

Recycling reduces waste in production.

Benefits of High-Quality Mold Bases

- Consistent Output

Strong bases ensure defect-free parts. - Cost Savings

Durable bases reduce replacements. - Faster Production

Accurate bases minimize downtime. - Customer Satisfaction

Reliable molds meet client expectations.

How to Choose the Right Injection Mould Company

- Experience

Look for companies with proven expertise. - Technology

Advanced tools ensure precision. - Reputation

Check reviews from other clients. - Support Services

Good companies guide you through the process.

Applications of Mold Bases

- Automotive Parts

Used for dashboards, bumpers, and more. - Medical Devices

Essential for high-precision components. - Consumer Goods

Mold bases create consistent everyday items. - Construction Equipment

Molds for durable tools rely on strong bases.

Future Trends in Mold Base Production

- Automation

Machines will handle more tasks. - AI Integration

Predictive tools will improve accuracy. - Eco-Friendly Materials

Companies will focus on sustainability. - Faster Turnarounds

Innovations will reduce lead times.

High-quality mold bases are vital. They ensure consistent performance in Injection Molding. An Injection Mould Company combines advanced tools with skilled Mold Makers. This results in durable and precise Injection Molds.

Invest in quality mold bases today. It saves time and money. It also improves product reliability. Choose a trusted Injection Mould Company for the best results.