The automotive industry demands precision. Interior components require high-quality designs. An Injection Mould Company plays a key role. They create reliable solutions for modern vehicles.

1. Importance of Injection Molding for Interiors

Injection Molding is critical for car interiors. It produces parts with exact dimensions. Smooth finishes are essential. These components enhance the vehicle’s look. Mold Makers ensure each piece fits perfectly.

2. Common Automotive Interior Parts

Many car parts come from Injection Molds. Examples include:

- Dashboard panels

- Door handles

- Seat covers

- Air vent frames

These parts must be durable. They must also be lightweight.

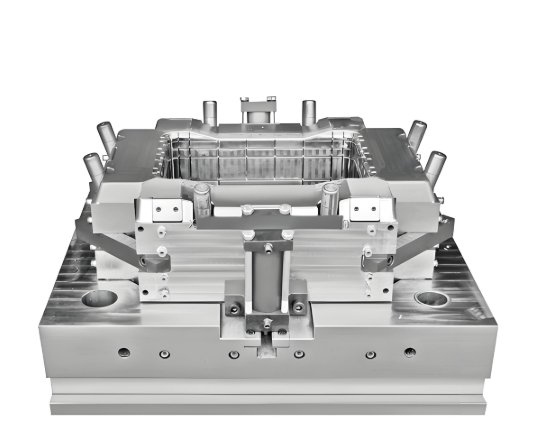

3. High Precision in Injection Molds

Accuracy is vital. Interior parts need consistent quality. Mold Makers use advanced tools to achieve this. Precise Injection Molds ensure perfect parts every time.

4. Material Selection for Interiors

Materials affect durability. Injection Mould Companies work with different plastics. Popular options include:

- ABS: Strong and heat-resistant

- Polycarbonate: Durable and clear

- Polypropylene: Lightweight and flexible

These materials meet automotive standards.

5. Customization for Unique Designs

Car interiors vary by brand. Injection Mould Companies offer custom solutions. Mold Makers create designs that match specific needs. Custom molds bring unique interiors to life.

6. Sustainability in Automotive Molding

Sustainability matters. Car manufacturers prefer eco-friendly options. Injection Mould Companies now use recycled materials. Energy-efficient machines reduce waste.

7. Challenges in Automotive Molding

Interior components face challenges. High temperatures and UV exposure can damage parts. Mold Makers address this by selecting durable materials. They also design molds to withstand tough conditions.

8. Multi-Shot Molding Techniques

Multi-shot molding is common. This technique combines materials in one process. Injection Molding creates parts with different textures. For example, soft-touch dashboards use this method.

9. Role of Advanced Technology

Technology drives progress. Injection Mould Companies use CAD software to design molds. CNC machines ensure precise mold cutting. These tools reduce errors and improve efficiency.

10. Quality Testing for Automotive Interiors

Testing is crucial. Injection Mould Companies check molds thoroughly. Tests include:

- Strength analysis

- Temperature resistance

- UV testing

This ensures long-lasting interior parts.

11. Fast Prototyping for Interior Design

Prototypes help manufacturers test designs. Injection Mould Companies use 3D printing for quick prototyping. Clients can evaluate parts before full production.

12. Lightweight Solutions for Efficiency

Lightweight materials improve fuel efficiency. Mold Makers focus on weight optimization. Thin yet strong components reduce vehicle weight.

13. Trends in Automotive Injection Molding

Trends shape the industry. Key innovations include:

- Smart surfaces with integrated sensors

- Decorative trims with unique finishes

- Biodegradable plastics

Injection Mould Companies adapt to these trends.

14. Benefits of Partnering with an Injection Mould Company

Working with an expert offers many advantages:

- High-quality Injection Molds

- Faster production times

- Cost-effective solutions

- Tailored designs

15. Why Choose the Right Mold Maker

The right Mold Maker ensures success. Look for a company with experience in Injection Molding. Check for advanced technology and proven results.

Automotive interiors rely on precision. Injection Mould Companies provide solutions to meet this demand. They create durable and innovative Injection Molds. Choosing the right partner guarantees quality. The future of car interiors is in skilled hands.