Consumer products must last. Durability is key. This is where an Injection Mould Company excels. They create long-lasting solutions for daily use. Their expertise ensures quality products every time.

1. The Power of Injection Molding

Injection Molding is essential for durable goods. It creates strong parts quickly. This process uses heat and pressure. Materials are melted and injected into molds. Once cooled, solid and reliable products emerge.

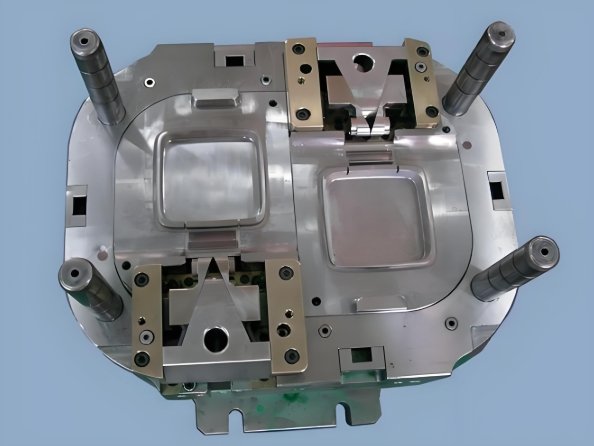

2. What Makes Injection Molds Unique?

Injection Molds shape the product. They must be precise. High-quality molds guarantee durable results. A skilled Mold Maker ensures molds meet exact specifications. These molds handle stress and repeated use.

3. Consumer Products Made with Injection Molding

Many everyday items use this process. Examples include:

- Kitchen utensils

- Storage containers

- Electronic casings

- Furniture components

These products require strength. They must withstand wear and tear.

4. Material Selection Matters

Materials play a big role. Injection Mould Companies choose durable plastics. Common options include:

- Polycarbonate for strength

- ABS for toughness

- Polypropylene for flexibility

The right material enhances product lifespan.

5. Customization for Consumer Products

Consumers demand variety. Injection Mould Companies offer custom designs. Mold Makers create molds for specific needs. This allows companies to produce unique products.

6. Precision in Mold Making

Precision is critical. Mold Makers use advanced tools for accuracy. CNC machines and CAD software ensure every detail is perfect. This precision boosts product durability.

7. Sustainability in Injection Molding

Sustainability matters today. Eco-friendly practices are growing. Recycled plastics are used more often. Energy-efficient machines reduce waste. Injection Mould Companies embrace these changes.

8. How Testing Ensures Durability

Testing is vital. Products must pass stress tests. These tests simulate real-world conditions. Injection Mould Companies ensure parts can handle impact, heat, and pressure. Testing guarantees quality.

9. Multi-Cavity Molds for Efficiency

Multi-cavity molds are popular. They produce several parts at once. This speeds up production. It also ensures consistency. Injection Molding becomes faster and more efficient.

10. The Role of Advanced Technology

Technology improves the process. Automated machines reduce errors. 3D printing helps create prototypes. These advancements save time and money. They also enhance mold accuracy.

11. Lightweight Yet Strong Designs

Durable products can be lightweight. Injection Mould Companies focus on reducing material weight. Lightweight items are easier to handle. Yet they remain strong and reliable.

12. Trends in Consumer Product Injection Molding

Trends shape the market. Popular trends include:

- Smart device casings

- Recyclable materials

- Modular designs

Injection Mould Companies adapt to these needs.

13. Why Choose the Right Injection Mould Company?

The right partner makes a difference. Look for experience in Injection Molding. Check their portfolio for proven results. Advanced tools and skilled Mold Makers are a must.

14. Benefits of Injection Molding for Consumers

This process offers many advantages:

- High durability

- Consistent quality

- Cost-effective production

- Customization options

Consumers receive products they can trust.

15. Building Long-Lasting Partnerships

Working with an Injection Mould Company creates long-term value. They understand durability. Their expertise supports product innovation.

Durability drives consumer satisfaction. Injection Mould Companies play a vital role. They deliver quality Injection Molds and expert Injection Molding. These companies shape the future of consumer goods. Choosing the right Mold Maker ensures success.