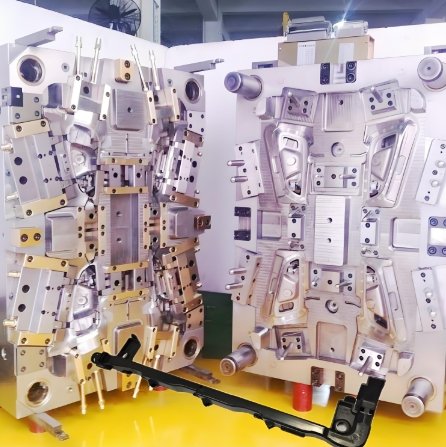

Complex tooling is challenging. It requires precision and expertise. An injection mould company specializes in meeting these demands. Their injection molding techniques and skilled mold makers deliver exceptional results. Quality injection molds ensure every project is a success.

Understanding Complex Tooling

Complex tooling involves intricate designs. These designs often include multiple components. Precision is critical. Small errors can lead to big problems.

An injection mould company ensures accuracy. Their advanced machines handle detailed designs. This capability supports various industries.

Why Injection Molding is Ideal for Complex Tooling

Injection molding is versatile. It handles high-precision requirements easily. The process allows the creation of detailed parts.

An injection mould company uses specialized techniques. These techniques produce consistent results. Every part matches the design specifications.

The Role of Skilled Mold Makers

Molds are the foundation of tooling. Skilled mold makers craft them with care. They ensure every mold is flawless.

Precision is their priority. A skilled mold maker uses advanced tools. This ensures each mold supports complex designs.

Injection Molds for Unique Designs

Unique designs need custom molds. An injection mould company provides tailored solutions.

Their injection molds support intricate patterns. These molds also accommodate multiple materials. This flexibility meets diverse project needs.

Materials for Complex Tooling

Material choice affects tooling quality. An injection mould company offers various options. These include durable plastics and metals.

Each material has specific properties. Injection molding ensures compatibility. This approach enhances part performance.

Challenges in Complex Tooling

Complex tooling has unique challenges. These include maintaining precision and reducing errors.

An injection mould company tackles these issues. They use advanced machines for accuracy. Regular quality checks ensure reliability.

Technology Drives Success

Technology improves tooling. An injection mould company invests in innovation.

They use 3D design software for precise modeling. Automation speeds up the production process. These advancements reduce lead times.

Applications of Complex Tooling

Complex tooling suits many industries. Examples include:

- Automotive: Engine components and dashboards

- Aerospace: Lightweight, durable parts

- Electronics: Intricate circuit housings

- Medical devices: Precision instruments

An injection mould company meets each industry’s unique needs.

Cost-Effective Solutions for Complex Tooling

Cost is a concern in tooling. An injection mould company offers affordable options.

Reusable injection molds reduce expenses. Durable materials support long-term use. These measures save money.

Sustainability in Tooling

Sustainability is vital. An injection mould company adopts eco-friendly practices.

They use recyclable materials. Efficient injection molding reduces waste. These efforts align with green initiatives.

Collaborative Approach for Complex Tooling

Collaboration improves results. An injection mould company works closely with clients.

Clients share ideas and requirements. Engineers refine these into practical solutions. Mold makers bring these solutions to life.

Future Trends in Complex Tooling

The future of tooling is exciting. New materials and faster machines are emerging.

An injection mould company stays ahead of these trends. Their expertise ensures quality results.

Complex tooling demands expertise. An injection mould company delivers precise solutions.

Injection molding supports intricate designs. Skilled mold makers craft high-quality injection molds. These efforts meet industry standards.

For reliable tooling, trust an experienced injection mould company. They combine innovation with precision to exceed expectations.