Material selection is critical in manufacturing. An injection mould company focuses on choosing the right materials. These choices ensure quality products. Materials also affect the performance of injection molds. Skilled mold makers guide this process using advanced injection molding techniques.

The Importance of Material Selection

Materials influence every product’s properties. Strength, durability, and flexibility all depend on material choice.

An injection mould company considers these factors carefully. They balance cost, quality, and application needs. This approach guarantees customer satisfaction.

Factors Considered in Material Selection

- Product Application

The end-use determines material needs. Durable plastics suit automotive parts. Flexible materials fit packaging solutions. - Mechanical Properties

Strength and elasticity are key. An injection mould company tests materials for these properties. This ensures the product performs as expected. - Thermal Stability

Heat resistance matters in many industries. Injection molding heats materials. Selected materials must withstand these conditions. - Cost Efficiency

Budget constraints affect choices. An injection mould company selects affordable options without compromising quality.

Common Materials in Injection Molding

- Polypropylene (PP)

PP is versatile and cost-effective. It resists heat and chemicals. Mold makers often use it for packaging and containers. - Polycarbonate (PC)

PC is strong and transparent. It’s ideal for electronics and lenses. - Acrylonitrile Butadiene Styrene (ABS)

ABS combines strength and flexibility. It’s perfect for automotive and consumer products. - Polyethylene (PE)

PE offers excellent durability. It’s widely used in pipes and bottles.

The Role of Mold Makers in Material Selection

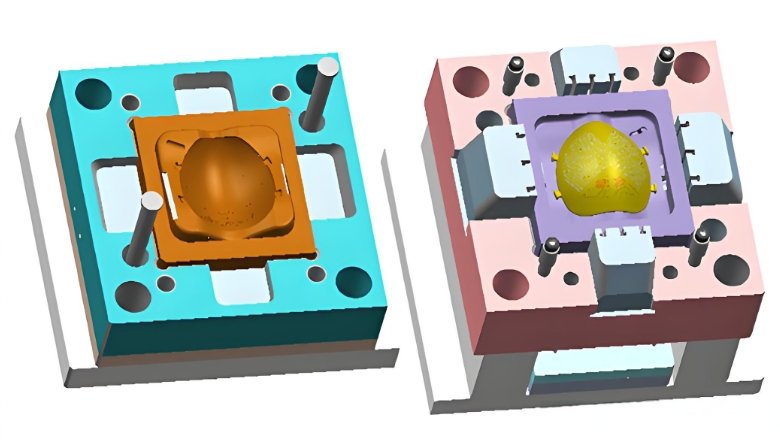

Mold makers understand material properties. They ensure chosen materials suit the product design.

Molds must handle material behavior during injection molding. Skilled mold makers adjust mold designs to accommodate this. This expertise minimizes defects.

Challenges in Material Selection

Choosing the right material isn’t simple. Each project has unique requirements.

An injection mould company faces challenges like:

- Balancing cost and quality

- Ensuring material compatibility with molds

- Meeting environmental standards

These issues require careful analysis and experience.

Sustainability in Material Selection

Sustainability is a growing concern. An injection mould company uses eco-friendly materials.

Recycled plastics reduce environmental impact. Biodegradable options support green initiatives. These choices align with global sustainability goals.

Testing Materials for Injection Molds

Testing ensures materials meet standards. An injection mould company performs rigorous evaluations.

These tests assess:

- Strength and flexibility

- Heat resistance

- Chemical compatibility

The results guide material selection. This guarantees product performance.

Innovations in Material Selection

Technology drives new materials. An injection mould company stays updated on trends.

Nanocomposites and bio-based plastics are emerging options. These materials offer unique benefits. They enhance the capabilities of injection molding.

Applications of Different Materials

- Automotive

Durable plastics reduce vehicle weight. This improves fuel efficiency. - Medical Devices

Biocompatible materials ensure patient safety. - Electronics

Heat-resistant plastics protect sensitive components. - Consumer Products

Flexible materials create user-friendly items.

Cost-Effective Solutions in Material Selection

Material costs impact production budgets. An injection mould company balances affordability and quality.

Reusable injection molds reduce long-term costs. Durable materials support efficient manufacturing. These strategies save money without sacrificing standards.

The Future of Material Selection

The future is exciting. An injection mould company will embrace advanced materials.

3D printing supports prototyping with new materials. Sustainable plastics will dominate markets. These innovations improve injection molding processes.

Collaboration Improves Material Selection

Clients play a role in material choice. An injection mould company collaborates closely with them.

Clients share product needs and preferences. Engineers suggest suitable materials. Mold makers optimize molds for these materials.

Material selection defines product success. An injection mould company ensures this process is thorough.

Injection molding transforms chosen materials into high-quality products. Skilled mold makers and advanced injection molds support this effort.

Sustainability and innovation drive material choices. For reliable results, trust an experienced injection mould company. Their expertise guarantees products that exceed expectations.