An injection mould company is essential for complex parts. These parts often have intricate designs. They require advanced skills and tools. The entire process must be precise.

With injection molding, such parts become possible. Skilled mold makers create molds for every detail. These molds ensure accuracy. The result is high-quality products.

Understanding Complex Part Assembly

Complex parts often have multiple functions. They may include moving components or tight tolerances. Assembly of such parts is challenging.

An injection mould company simplifies this. They design injection molds that fit perfectly. Each part is molded to match the others.

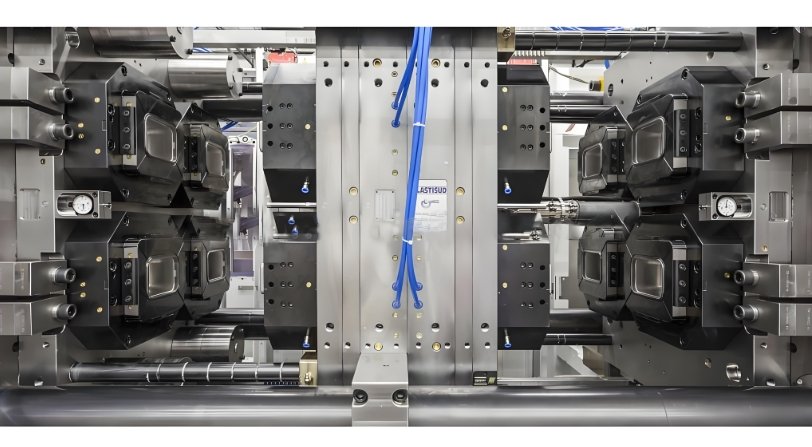

Advanced injection molding machines handle intricate designs. These machines use high pressure and heat. This ensures the molten material fills every cavity.

Designing for Complex Parts

The first step is design. Engineers work closely with clients. They understand the requirements.

The design must consider functionality. It must also suit injection molding. Engineers use CAD software for accuracy.

A good design avoids weak spots. It considers material flow and shrinkage. This prevents defects during molding.

Material Selection for Complex Parts

Material choice is crucial. Complex parts need durable materials. They must handle stress and temperature.

An experienced injection mould company helps choose the best material. Engineers evaluate strength, flexibility, and cost.

Common materials include ABS, nylon, and polycarbonate. These work well for intricate designs.

The Role of Mold Makers

Mold makers play a key role. They create molds for the parts. These molds must be precise.

Every mold starts with a steel or aluminum block. The mold maker machines it into shape. They ensure it matches the design.

Each mold undergoes testing. It must produce accurate parts repeatedly. Poor molds lead to defects.

Injection Molding for Complex Parts

The core process is injection molding. It starts with feeding raw material into a hopper. The material melts inside the machine.

The molten material is injected into the mold. High pressure ensures it fills every cavity. After cooling, the part solidifies.

Modern machines handle intricate designs. They produce parts with tight tolerances.

Assembly of Molded Parts

Complex parts often need assembly. This involves joining molded components.

An injection mould company offers assembly services. This saves clients time and effort.

Assembly methods include:

- Snap Fit: Parts lock together without tools.

- Welding: Heat joins plastic parts.

- Adhesives: Glue holds components together.

Quality Control in Complex Part Assembly

Quality is essential. Every part must meet specifications. An injection mould company inspects parts at every stage.

Quality checks include:

- Dimensional Accuracy: Measurements must match the design.

- Surface Finish: Smooth surfaces are checked for flaws.

- Functionality Tests: Parts are tested for performance.

Defects like warping or misalignment are fixed immediately.

Applications of Complex Part Assembly

- Automotive Industry

Dashboard panels, engine components, and safety parts require precision. - Medical Devices

Complex assemblies like syringes and surgical tools rely on accuracy. - Electronics

Parts like connectors and casings fit perfectly. - Consumer Products

Household items like appliances and toys include intricate parts.

Advantages of an Experienced Injection Mould Company

- Precision

Parts fit together perfectly. - Efficiency

The process is fast and cost-effective. - Customization

Clients get solutions tailored to their needs. - Durability

High-quality injection molds produce reliable parts. - Scalability

Mass production meets high demand.

Challenges in Complex Part Assembly

- Design Issues

Flaws in design lead to defects. A skilled injection mould company avoids these. - Material Limitations

Not all materials suit intricate designs. Engineers must choose carefully. - High Costs

Complex molds are expensive. However, long-term benefits outweigh the cost.

Technology in Injection Molding

Modern technology enhances injection molding. Advanced machines improve speed and accuracy.

Automation reduces human error. Robots handle assembly efficiently.

AI assists in quality checks. It detects minute flaws. This ensures consistent results.

Sustainability in Complex Part Production

Eco-friendly practices are growing. An injection mould company can reduce waste.

Recycled materials are often used. Energy-efficient machines lower power usage.

Sustainable practices benefit the environment and clients.

How to Choose the Right Injection Mould Company

- Experience

Choose a company with years of expertise. - Technology

Ensure they use modern tools. - Customization

Look for tailored solutions. - Quality Assurance

Check for strict quality control measures. - Customer Support

Good communication ensures smooth projects.

An injection mould company specializes in complex parts. They combine design, molding, and assembly.

Skilled mold makers craft precise injection molds. Advanced injection molding machines ensure accuracy.

Clients benefit from high-quality, reliable solutions. For complex part assembly, choose an experienced injection mould company.