An injection mould company plays a vital role in manufacturing. They specialize in creating injection molds. Multi-cavity molds are an advanced solution. They allow for faster production. Each cavity produces a part in one cycle.

This article explores how they help industries.

What Are Multi-Cavity Molds?

Multi-cavity molds have multiple cavities. Each cavity forms a part. Instead of making one part, multiple parts are made at once.

This speeds up injection molding. Efficiency improves. Costs are reduced.

Advantages of Multi-Cavity Molds

1. Increased Production

Multi-cavity molds multiply output. A single cycle makes many parts.

2. Reduced Costs

Mass production lowers costs. The same machine produces more parts.

3. Consistent Quality

All parts from one mold are identical. Quality remains consistent.

4. Faster Delivery

High production speed meets tight deadlines.

How Injection Mould Companies Create Multi-Cavity Molds

Designing multi-cavity molds requires expertise. A skilled mold maker ensures success.

1. Understanding Client Needs

The injection mould company begins by discussing the project. Clients share:

- The number of parts needed.

- Material preferences.

- Design specifications.

This information guides the process.

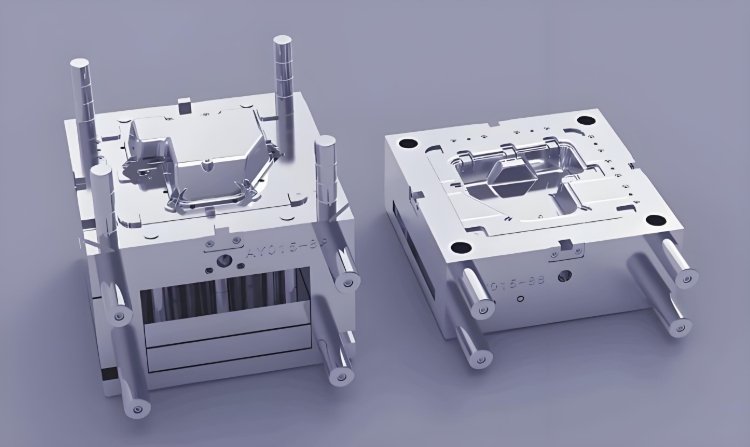

2. Designing the Mold

Next, engineers design the mold. Advanced software is used. The design ensures:

- Precise cavity alignment.

- Proper cooling channels.

- Efficient ejection systems.

3. Material Selection

The right materials are chosen for the mold. Common choices include steel and aluminum. Steel offers durability. Aluminum is ideal for prototypes.

4. Manufacturing the Mold

Mold makers build the mold using CNC machines. High precision is required. Each cavity must be identical.

5. Testing and Optimization

The mold is tested before production. Test runs identify any flaws. Adjustments ensure perfect results.

Applications of Multi-Cavity Molds

Multi-cavity molds are used in many industries.

1. Automotive

Car manufacturers need thousands of identical parts. Multi-cavity molds meet this demand.

2. Medical Devices

Medical parts require precision. Multi-cavity molds ensure accuracy.

3. Consumer Electronics

Electronics need small, detailed parts. Multi-cavity molds handle complex designs.

4. Packaging

Bottles and caps are mass-produced using these molds.

Challenges in Multi-Cavity Mold Production

Creating multi-cavity molds is complex. Challenges include:

1. Maintaining Uniformity

All cavities must produce identical parts. Variations affect quality.

2. Managing Cooling

Cooling systems must be balanced. Uneven cooling causes defects.

3. Handling Ejection

Parts must eject smoothly. Improper ejection damages molds.

4. Material Wear

High production cycles wear molds quickly. Durable materials are essential.

Why Choose an Injection Mould Company for Multi-Cavity Molds?

An experienced injection mould company ensures success. Their expertise includes:

1. Skilled Mold Makers

Expert mold makers craft precise molds. They handle complex designs with ease.

2. Advanced Technology

Modern tools improve accuracy. CNC machines and CAD software are standard.

3. Comprehensive Support

The company guides clients through every step. From design to production, they provide solutions.

4. Quality Assurance

Strict testing ensures consistent quality. Clients receive flawless parts.

Cost Considerations for Multi-Cavity Molds

Multi-cavity molds cost more initially. However, long-term savings are significant.

Costs depend on:

- Number of cavities.

- Mold material.

- Design complexity.

High output reduces per-part costs.

Future of Multi-Cavity Molds

Technology continues to evolve. AI and automation improve mold design. Materials like hybrid alloys extend mold life.

The best injection mould companies adopt these advancements. Clients benefit from faster, cheaper, and better production.

Multi-cavity molds revolutionize injection molding. They increase production, cut costs, and ensure quality.

A reliable injection mould company delivers these solutions. Skilled mold makers use advanced tools to meet client needs.

Choose an expert for your next project. Multi-cavity molds guarantee success.