The manufacturing industry is evolving. Technology drives faster and better production methods. Rapid prototyping is leading this change. It helps companies create and test products quickly. For an injection mould company, it opens new doors for innovation.

What is Rapid Prototyping?

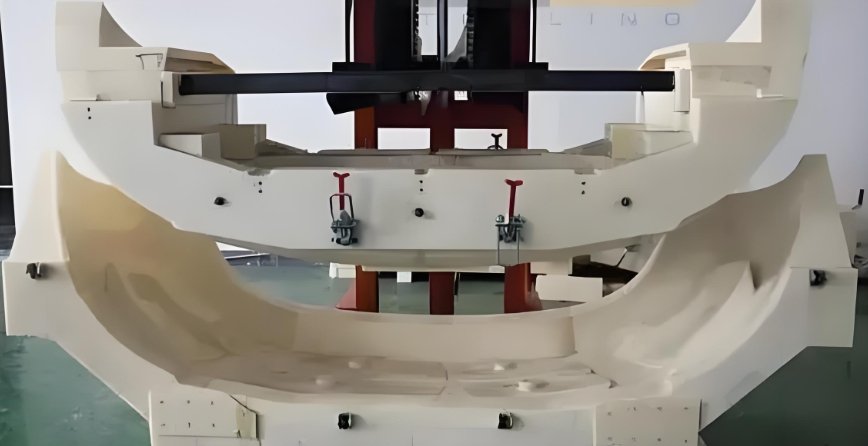

Rapid prototyping is the fast creation of product models. These models help test designs before mass production. Technologies like 3D printing and CNC machining are often used. Prototypes can be functional or visual, depending on the need.

Why Rapid Prototyping is Crucial

Speed is essential in today’s market. Rapid prototyping reduces development time. It also lowers costs. Testing early prevents expensive mistakes. An injection mould company benefits from faster mold designs.

Technological Advances in Prototyping

New technologies make rapid prototyping better. 3D printers are faster and more accurate. CNC machines handle complex designs. Advanced software simplifies design creation. These innovations improve efficiency.

Benefits for Injection Mould Companies

An injection mould company gains many advantages from rapid prototyping. It speeds up mold creation. It ensures designs are accurate. Errors are identified early. This improves customer satisfaction.

Customization Made Easy

Manufacturers now focus on personalized products. Rapid prototyping supports customization. It allows quick changes to designs. This flexibility is crucial for meeting customer needs.

Reducing Time-to-Market

Time-to-market is a key factor for success. Rapid prototyping significantly shortens this time. Prototypes can be created, tested, and modified quickly. This gives companies a competitive edge.

Cost Savings in Manufacturing

Producing faulty products is expensive. Rapid prototyping identifies problems early. This avoids wasting materials. For an injection mould company, this reduces production costs.

Eco-Friendly Prototyping

Sustainability is a growing concern. Rapid prototyping reduces waste by using materials efficiently. Many processes are also energy-efficient. This supports eco-friendly practices in manufacturing.

Applications in Injection Mould Companies

Prototypes help create better molds. Functional tests ensure parts fit perfectly. Visual models show customers what to expect. In an injection mould company, these applications improve overall quality.

Challenges in Rapid Prototyping

Every technology faces challenges. Rapid prototyping requires skilled workers. Initial setup costs can be high. Material limitations affect design options. However, ongoing advancements address these issues.

The Role of Automation

Automation enhances rapid prototyping. Machines work faster with minimal human input. Automation ensures consistent quality. An injection mould company can automate mold production for better efficiency.

The Impact of AI on Prototyping

Artificial Intelligence (AI) is reshaping manufacturing. AI optimizes designs automatically. It predicts performance before creating prototypes. This reduces trial-and-error steps. AI integration improves rapid prototyping significantly.

Future Trends in Rapid Prototyping

The future holds exciting possibilities. Materials will become more advanced. Processes will be faster and cheaper. Virtual reality may allow prototype testing without physical models. These trends will benefit every injection mould company.

Global Adoption of Prototyping

Rapid prototyping is now a global practice. Companies worldwide use it to stay competitive. International collaboration enhances technology sharing. This boosts innovation everywhere.

Improving Collaboration with Prototypes

Prototypes help teams communicate better. Designers, engineers, and customers can visualize ideas. Feedback becomes more constructive. This improves the final product.

Supporting Small Businesses

Small businesses often struggle with high production costs. Rapid prototyping makes manufacturing more accessible. It reduces initial investment. Small injection mould companies can now compete with larger firms.

Educating the Workforce

Skilled workers are crucial for effective prototyping. Training programs focus on using new tools. An injection mould company benefits from an educated workforce. This ensures smoother operations.

Building Stronger Customer Relationships

Prototypes give customers a preview of the final product. This builds trust. Customers can request changes before production. Rapid prototyping strengthens business relationships.

Rapid prototyping is transforming manufacturing. It saves time, reduces costs, and improves quality. For an injection mould company, it offers endless opportunities. As technology advances, the future of manufacturing looks brighter than ever.