In today’s fast-paced world, creating prototypes quickly is essential. Rapid Prototyping simplifies this process. It uses advanced tools to create models from digital designs. An injection mould company plays a key role in delivering precise prototypes.

What is Rapid Prototyping?

Rapid Prototyping creates physical models from digital files. It speeds up the design process. Companies use it to test ideas before production. An injection mould company ensures high-quality results.

Types of Rapid Prototyping Technologies

1. 3D Printing

3D printing is the most common method. It builds objects layer by layer. It uses materials like plastics, resins, or metals. The process is fast and affordable.

2. CNC Machining

CNC machining is highly precise. It removes material from a block to create a shape. It works with metals and plastics. An injection mould company often uses this for mold creation.

3. Stereolithography (SLA)

SLA uses light to harden liquid resin. It creates detailed prototypes. This method is ideal for small, intricate designs.

4. Selective Laser Sintering (SLS)

SLS fuses powder materials with a laser. It creates durable parts. Companies use it for functional prototypes.

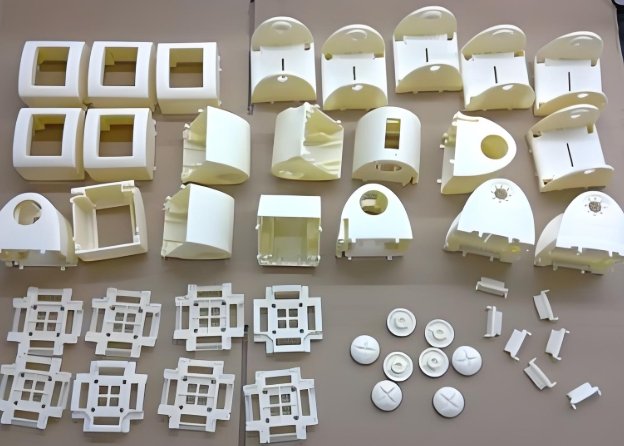

5. Injection Molding for Prototyping

Injection molding is perfect for small-batch prototypes. It ensures accurate and consistent results. An injection mould company excels in this method.

How Does Rapid Prototyping Work?

- Design Creation

Engineers create a digital file. They use CAD software for detailed designs. - Material Selection

The right material is chosen. This depends on the prototype’s purpose. - Prototyping Method

A suitable technology is selected. This ensures speed and precision. - Production

The machine builds the prototype. It follows the digital design exactly.

Advantages of Rapid Prototyping

Speed

Rapid Prototyping drastically reduces production time.

Cost-Effective

It uses minimal materials. Labor costs are also low.

Flexibility

It allows easy changes. Revisions are quick and simple.

Precision

It creates highly accurate models. An injection mould company ensures precise results.

Applications of Rapid Prototyping

1. Automotive Industry

Car companies use Rapid Prototyping for parts testing. It speeds up design revisions.

2. Medical Field

Doctors use it for surgical planning. It also helps in creating custom prosthetics.

3. Aerospace Sector

Engineers create complex aircraft parts. Prototypes test designs before mass production.

4. Consumer Products

Companies test product designs. They ensure functionality before launch.

Role of Injection Mould Companies in Rapid Prototyping

An injection mould company provides tools and expertise. They handle complex designs with precision. They also ensure scalability for larger projects.

Challenges in Rapid Prototyping

Material Limitations

Not all materials are compatible.

Initial Costs

Some machines are expensive.

Strength of Prototypes

Not all methods produce durable parts.

An injection mould company helps overcome these challenges.

Future of Rapid Prototyping

The technology continues to evolve. New methods improve speed and accuracy. An injection mould company adapts to these advancements.

Rapid Prototyping transforms manufacturing. It saves time and money. With the help of an injection mould company, businesses achieve better results. Embrace this technology for faster product development.