What Is Rapid Prototyping?

Rapid Prototyping is a fast process to make physical models. It uses digital designs to create real objects. Designers and engineers use it to test ideas. The process is quick, accurate, and efficient.

Custom manufacturing depends on it. It ensures products meet customer needs. Injection mould companies play a key role in this.

Why Is Rapid Prototyping Important in Custom Manufacturing?

Custom manufacturing focuses on unique products. Every product must meet specific requirements. Rapid Prototyping allows quick design adjustments. It tests products before final production.

Using Rapid Prototyping saves time and money. It improves accuracy. It ensures customer satisfaction.

Types of Rapid Prototyping in Manufacturing

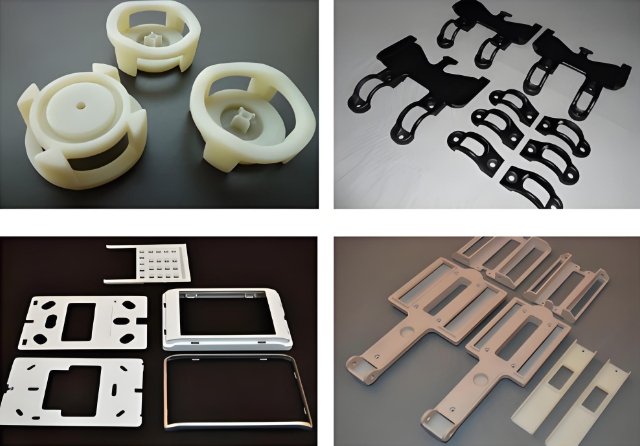

1. 3D Printing

This method builds objects layer by layer. It uses materials like plastic, resin, or metal. It is fast and precise.

2. CNC Machining

This technique cuts material to create shapes. It works with metals and plastics. It ensures high accuracy.

3. Injection Moulding Prototypes

Injection mould companies use this method. It creates molds for testing. These molds ensure perfect parts before mass production.

4. Vacuum Casting

This process uses silicone molds. It is ideal for small production runs.

5. Sheet Metal Prototyping

Laser cutting and bending shape metal sheets. This method suits flat designs.

Applications of Rapid Prototyping

1. Product Development

Rapid Prototyping speeds up product design. Companies test shapes and sizes quickly.

2. Medical Equipment

Prototypes ensure devices are safe and functional.

3. Automotive Industry

Car manufacturers test parts for durability. Prototypes improve safety and efficiency.

4. Consumer Goods

Companies test designs for household products.

5. Aerospace Industry

Injection mould companies support aerospace projects. They test parts for strength and reliability.

How Rapid Prototyping Supports Customization

1. Faster Design Changes

Designers make quick adjustments. Prototypes allow immediate testing.

2. Better Collaboration

Teams work together easily. Clients give feedback on prototypes.

3. Cost Efficiency

Errors are corrected early. This reduces waste.

4. High Accuracy

Rapid Prototyping delivers precise models. This ensures better final products.

5. Scalability

Custom designs are tested before mass production. This minimizes risks.

Benefits of Partnering with an Injection Mould Company

1. Expert Advice

Injection mould companies guide design improvements. They recommend materials and processes.

2. High-Quality Prototypes

Their experience ensures precision.

3. Efficient Production

Prototypes transition smoothly into full-scale production.

4. Material Options

They provide a variety of materials. These suit different project needs.

5. Long-Term Partnerships

Many companies form ongoing relationships. This supports future projects.

Challenges in Rapid Prototyping

1. Material Limitations

Some materials are not suitable for final products.

2. Cost of Equipment

Machines used for Rapid Prototyping can be expensive.

3. Accuracy Limits

Prototypes may differ slightly from final products.

4. Time for Complex Projects

Highly detailed models may take longer to create.

Innovations in Rapid Prototyping

New materials are being developed. These improve strength and flexibility. Faster machines reduce production time. Injection mould companies are adopting AI for better designs.

How to Choose a Rapid Prototyping Partner

1. Experience

Look for companies with proven success.

2. Capabilities

Ensure they offer various prototyping methods.

3. Customer Support

A good partner offers clear communication.

4. Reviews and Ratings

Check reviews before making a decision.

5. Cost Transparency

Ask for detailed quotes.

Future of Rapid Prototyping in Custom Manufacturing

The industry is growing fast. Technology will improve. Rapid Prototyping will be faster and cheaper. Injection mould companies will offer more advanced services.

Rapid Prototyping is essential for custom manufacturing. It ensures fast design and testing. Partnering with an Injection mould company guarantees success. This combination delivers high-quality products. Choose a reliable partner to bring your ideas to life.