Rapid Prototyping uses advanced technologies to create models fast. SLA and SLS are two popular methods. They make accurate and functional prototypes.

An Injection Mould Company often relies on these techniques. Choosing the right method is critical. This article explores SLA and SLS.

What is SLA in Rapid Prototyping?

SLA Defined

SLA stands for Stereolithography. It uses a liquid resin. A laser hardens layers to build the prototype.

Benefits of SLA

- High precision.

- Smooth surfaces.

- Ideal for complex designs.

Applications of SLA

- Medical devices.

- Jewelry design.

- Consumer electronics.

What is SLS in Rapid Prototyping?

SLS Defined

SLS means Selective Laser Sintering. It uses powdered material. A laser fuses particles to form layers.

Benefits of SLS

- Strong prototypes.

- No support structures needed.

- Works with various materials.

Applications of SLS

- Automotive parts.

- Aerospace components.

- Customized tools.

SLA vs. SLS: Key Differences

| Feature | SLA | SLS |

|---|---|---|

| Material | Liquid resin | Powder |

| Precision | High | Moderate |

| Strength | Low | High |

| Surface Finish | Smooth | Rough |

| Cost | More affordable | Expensive |

How an Injection Mould Company Uses SLA and SLS

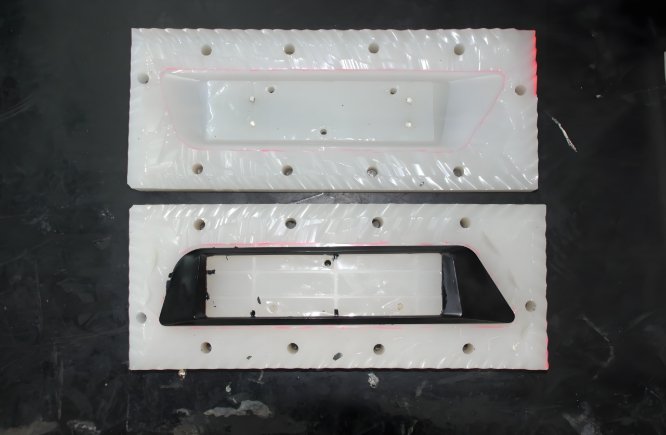

Prototyping Complex Molds

Both methods create accurate mold designs.

Speeding Up Production

SLA and SLS reduce time-to-market.

Ensuring Quality

High-precision prototypes ensure better final molds.

Advantages of SLA and SLS in Rapid Prototyping

Faster Iterations

Changes can be made quickly.

Reduced Costs

Avoid expensive manufacturing errors.

Improved Innovation

Experiment with new designs easily.

How to Choose Between SLA and SLS

Consider Your Needs

SLA works for smooth, detailed designs. SLS fits strong, functional parts.

Budget Constraints

SLA is more cost-effective for small projects.

Material Requirements

SLS offers more material options.

Design Complexity

SLA handles intricate details better.

Challenges of SLA and SLS

SLA Challenges

- Brittle prototypes.

- Limited material options.

SLS Challenges

- Rough surfaces.

- Higher costs.

The Role of an Injection Mould Company

Material Expertise

They help you choose the right material.

Technology Access

They use the latest SLA and SLS equipment.

Seamless Transition

They move prototypes to production with ease.

Future Trends in SLA and SLS

Faster Machines

New technologies speed up prototyping.

Eco-Friendly Materials

Sustainable options are growing.

AI Integration

AI optimizes the design process.

SLA and SLS are vital in Rapid Prototyping. Each method has unique benefits. An Injection Mould Company ensures you get the best results.

Choosing the right method boosts efficiency and reduces costs. Invest in the right tools for success.