Rapid Prototyping is changing engineering. It speeds up development. It improves designs. Partnering with an Injection Mould Company adds even more value.

Here are the top 10 ways engineers use Rapid Prototyping.

1. Concept Validation

Rapid Prototyping helps test ideas. Engineers create quick models. They assess feasibility before investing in production.

Why it Matters

This step prevents costly mistakes. Designers visualize ideas clearly.

2. Design Refinement

Engineers use Rapid Prototyping to refine designs. It identifies flaws early. Changes are easy to implement.

Example

Car manufacturers test aerodynamics. Small tweaks improve performance.

3. Material Testing

Rapid Prototyping allows material experimentation. Engineers evaluate different materials. They test durability and flexibility.

Benefit

It ensures products meet requirements. Prototypes reveal material behavior.

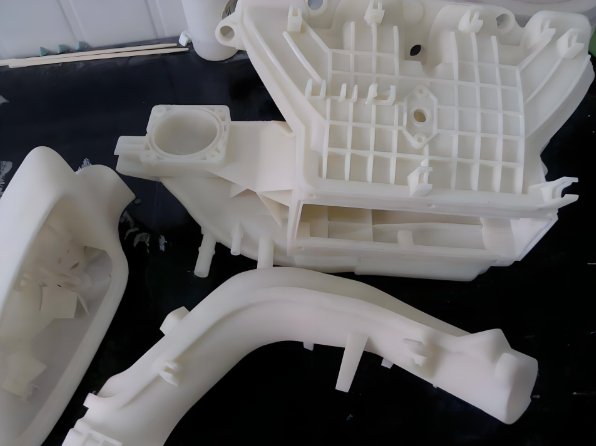

4. Functional Prototypes

Functional prototypes test usability. Engineers check moving parts. They assess mechanical performance.

Role of an Injection Mould Company

They help align prototypes with mold designs. This ensures smooth transitions.

5. Bridge Manufacturing

Small batches are made using prototypes. Engineers test production capabilities. This fills gaps before large-scale manufacturing.

Application

Electronics companies use this for initial runs. They gather customer feedback.

6. Custom Solutions

Rapid Prototyping enables unique designs. Engineers create tailored solutions. They cater to specific needs.

Example

Medical devices are often customized. Prototypes ensure perfect fits.

7. Educational Tools

Engineering students use prototypes. They learn by creating models. This builds practical skills.

Importance

Future engineers understand processes better.

8. Reverse Engineering

Prototypes recreate existing parts. Engineers replicate designs. This is helpful for repairs or upgrades.

Common Use

Aviation companies restore old components.

9. Collaboration Enhancement

Prototypes improve teamwork. Engineers and designers share tangible models. This fosters better communication.

Result

Fewer misunderstandings occur. Teams align quickly.

10. Integration with Mold Design

Rapid Prototyping aids mold creation. Engineers test mold designs. This ensures compatibility with final products.

Role of an Injection Mould Company

They bridge the gap between prototype and production.

Challenges in Using Rapid Prototyping

Cost Concerns

Some methods are expensive.

Material Limitations

Not all materials are compatible.

Accuracy Issues

Low-resolution prototypes can mislead.

Overcoming These Challenges

Work with Experts

An Injection Mould Company offers guidance.

Use Advanced Techniques

High-quality tools improve precision.

Choose Suitable Materials

Match materials to project needs.

Future of Rapid Prototyping in Engineering

Faster Production

Technologies are becoming quicker.

Sustainable Practices

Eco-friendly materials are emerging.

AI Integration

AI enhances design processes.

Rapid Prototyping is transforming engineering. Its applications are vast. Partnering with an Injection Mould Company maximizes benefits.

These top 10 uses highlight its importance. Embrace Rapid Prototyping for engineering success.