CAD and Rapid Prototyping go hand in hand. CAD stands for Computer-Aided Design. It creates precise digital models. These models guide Rapid Prototyping processes.

An Injection Mould Company relies on this link. CAD ensures design accuracy. Prototyping brings designs to life. Together, they optimize production.

What Is CAD?

CAD software creates 2D and 3D models. Engineers design everything from small parts to complex systems.

Features of CAD

- Precise measurements.

- Advanced simulation tools.

- Easy design modifications.

What Is Rapid Prototyping?

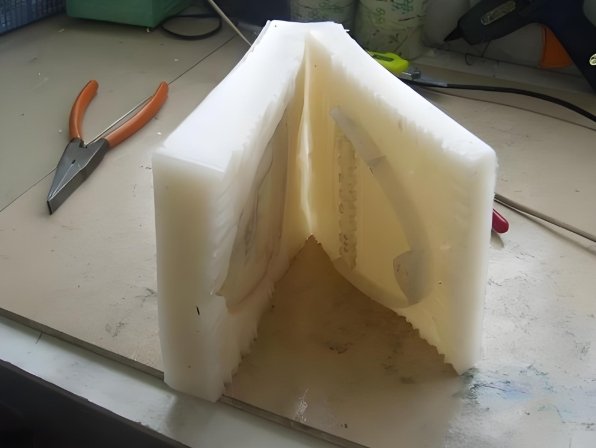

Rapid Prototyping turns digital models into physical objects. It uses technologies like 3D printing or CNC machining.

Advantages of Rapid Prototyping

- Speeds up product development.

- Reduces production errors.

- Allows early testing.

How CAD Integrates with Rapid Prototyping

1. Design Creation

CAD software builds the foundation. Engineers create detailed blueprints.

2. File Conversion

The CAD model converts into formats like STL. These files guide prototyping machines.

3. Prototype Production

Machines follow CAD instructions. They form prototypes layer by layer.

4. Testing and Refinement

Prototypes undergo real-world tests. Engineers adjust CAD designs as needed.

Why an Injection Mould Company Needs CAD and Prototyping

Accurate Mold Design

CAD ensures molds fit precisely. Rapid Prototyping verifies their functionality.

Faster Production

Prototypes catch errors early. This saves time during mold creation.

Improved Collaboration

CAD files are easy to share. Clients and engineers work together seamlessly.

Challenges in CAD and Rapid Prototyping

File Compatibility Issues

Not all CAD files work with prototyping machines.

Design Complexity

Highly detailed designs may take longer to prototype.

Cost Factors

Advanced CAD tools and materials can be expensive.

Overcoming Challenges

Use Compatible Software

Ensure CAD tools support prototyping formats.

Simplify Designs

Focus on essential details during initial stages.

Partner with Experts

Work with an experienced Injection Mould Company. They streamline the process.

Applications in Different Industries

Automotive

CAD designs vehicle components. Rapid Prototyping tests functionality.

Healthcare

Custom medical tools benefit from precise designs.

Consumer Electronics

Prototypes refine product enclosures and parts.

The Future of CAD and Rapid Prototyping

AI Integration

AI improves design accuracy. It automates repetitive tasks.

Sustainable Practices

Eco-friendly materials reduce environmental impact.

Faster Prototyping

New technologies enhance speed and precision.

CAD and Rapid Prototyping transform manufacturing. They ensure precision, speed, and efficiency. An Injection Mould Company leverages this link. They create reliable molds and products.

Invest in CAD tools and Rapid Prototyping. They are essential for modern design and production. These technologies streamline workflows and boost results.