Fashion evolves quickly. Designers face tight deadlines. Rapid Prototyping changes the game. It speeds up the creative process. An experienced Injection Mould Company plays a key role. Let’s explore how this technology reshapes fashion.

What Is Rapid Prototyping?

Definition

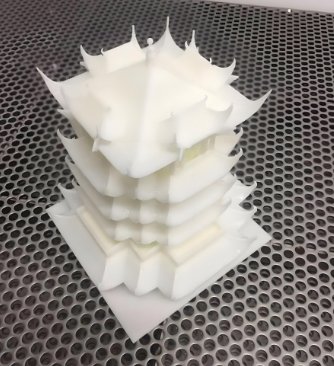

Rapid Prototyping creates physical models from digital designs.

Why It Matters

It helps test and refine ideas before mass production.

Common Tools

Designers use 3D printers and CNC machines.

Impact on Fashion Design

Faster Iterations

Designers can test multiple ideas quickly.

Reduced Waste

Creating digital samples reduces fabric and material use.

Enhanced Creativity

Prototypes allow designers to explore bold concepts.

Key Applications in Fashion

Accessories

Jewelry and handbags often use Rapid Prototyping. Prototypes ensure the perfect fit and finish.

Footwear

Shoe designers test comfort and durability with prototypes.

Garments

Complex patterns and intricate designs benefit from this method.

Role of an Injection Mould Company

Material Expertise

They suggest durable materials for fashion prototypes.

Precision Tools

Their advanced machines ensure accuracy.

Mass Production

They transition prototypes to large-scale production.

Benefits of Rapid Prototyping for Designers

Visual Realism

Prototypes look and feel like final products.

Faster Approvals

Clients and stakeholders approve designs quickly.

Reduced Costs

Less trial-and-error saves money.

Challenges in Fashion Prototyping

Material Limitations

Not all fabrics replicate well.

Learning Curve

Designers must understand new technologies.

Cost Barriers

Advanced tools can be expensive initially.

How to Overcome Challenges

Partner with Experts

Collaborate with an experienced Injection Mould Company.

Use Hybrid Approaches

Combine digital and traditional methods.

Invest in Training

Equip teams with knowledge of prototyping tools.

Future Trends

Sustainable Materials

Eco-friendly prototypes gain popularity.

AI Integration

AI predicts fashion trends and optimizes designs.

Faster Machines

Next-gen printers will reduce production time further.

Case Study: Success in Fashion

Real-World Example

A designer used Rapid Prototyping to create custom jewelry.

Process

The designer collaborated with an Injection Mould Company. They developed 3D-printed molds for unique pieces.

Result

The jewelry collection launched ahead of schedule.

Why Choose Rapid Prototyping?

Innovation

It fosters groundbreaking designs.

Flexibility

Designers can adjust models instantly.

Market Advantage

Faster launches lead to competitive edges.

The Future of Fashion and Prototyping

More Accessibility

Smaller brands will embrace this technology.

Personalization

Custom designs will dominate the market.

Global Collaboration

Designers and manufacturers will connect seamlessly.

Rapid Prototyping transforms fashion. It boosts speed, creativity, and efficiency. An expert Injection Mould Company enhances this process.

Fashion designers should embrace this technology. It helps them meet market demands faster. The future of fashion lies in rapid, innovative solutions.