Modern engineering thrives on speed and innovation. Rapid Prototyping makes this possible. It transforms ideas into tangible models quickly. Engineers use it to test and refine designs.

An experienced Injection Mould Company adds value to this process. They ensure accuracy and efficiency. This article explains why Rapid Prototyping is critical in engineering today.

What Is Rapid Prototyping?

Definition

Rapid Prototyping creates physical models quickly. These prototypes replicate final products.

Techniques

It includes 3D printing, CNC machining, and injection molding.

Purpose

Prototypes help test designs early. Engineers identify flaws and make adjustments fast.

The Role of Rapid Prototyping in Modern Engineering

1. Faster Design Cycles

Engineers create and refine designs quickly. This speeds up development.

2. Improved Accuracy

Prototypes allow detailed testing. Engineers catch errors early.

3. Enhanced Collaboration

Teams use prototypes to share ideas. It ensures everyone aligns with the project goals.

Benefits of Partnering with an Injection Mould Company

Expertise

A skilled Injection Mould Company ensures high-quality prototypes.

Advanced Tools

They use modern machines for precision.

Material Selection

They recommend the best materials for prototypes.

Reliable Support

They guide projects from start to finish.

Key Benefits of Rapid Prototyping in Engineering

1. Early Problem Detection

Prototypes reveal design flaws early.

2. Cost Efficiency

Fixing issues early saves money.

3. Design Flexibility

Engineers can tweak designs multiple times.

4. Market Advantage

Faster prototyping shortens time to market.

Popular Rapid Prototyping Methods

1. 3D Printing

This method creates detailed models fast.

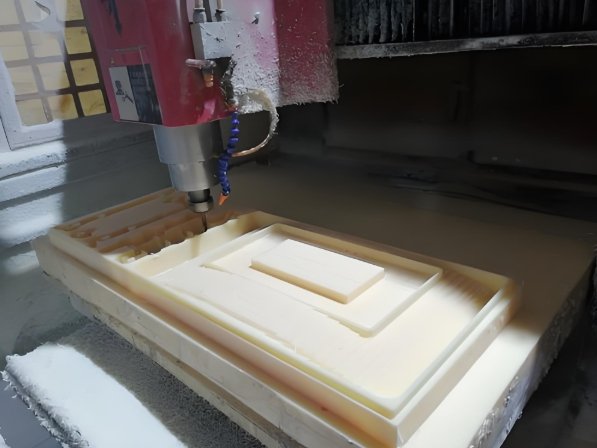

2. CNC Machining

It offers precision for functional parts.

3. Injection Molding

Ideal for producing prototypes with real-world materials.

Applications in Engineering

Automotive

Prototypes test parts like engines and dashboards.

Aerospace

Engineers use prototypes to improve aerodynamics.

Medical Devices

Prototypes ensure safety and compliance.

Consumer Products

Companies test designs before mass production.

Challenges in Rapid Prototyping

Time Constraints

Complex prototypes may take longer to produce.

Cost of Materials

High-quality materials can be expensive.

Design Complexity

Intricate designs require advanced techniques.

Solutions to Overcome Challenges

Partnering with Experts

Work with a reliable Injection Mould Company.

Using Advanced Tools

Modern machines reduce production time.

Budget Planning

Allocate resources for high-quality materials.

The Future of Rapid Prototyping in Engineering

AI Integration

Artificial intelligence will improve design accuracy.

Sustainable Materials

Eco-friendly options will dominate the market.

Faster Prototyping

Emerging technologies will reduce production time.

Global Collaboration

Teams will use virtual tools for worldwide prototyping.

Why Engineers Choose Rapid Prototyping

Innovation

It inspires creative solutions.

Speed

Prototypes accelerate project timelines.

Precision

Engineers ensure accuracy through detailed testing.

Versatility

It adapts to various industries and projects.

Choosing the Right Injection Mould Company

Proven Track Record

Check their experience with engineering projects.

Technology Access

Ensure they use advanced prototyping tools.

Material Expertise

They should offer a wide range of materials.

Strong Communication

Clear updates keep projects on track.

Rapid Prototyping is essential for modern engineering. It enables faster design cycles, cost savings, and improved accuracy. Prototypes bring ideas to life and refine them before production.

Partnering with an expert Injection Mould Company enhances the process. Their tools and expertise ensure top-quality results. With Rapid Prototyping, engineers can innovate, collaborate, and lead in competitive markets.