The automotive industry demands precision and durability. High-quality Automotive Injection Molds play a vital role in meeting these requirements. A skilled Mold Maker ensures every mold meets exact specifications. These solutions drive innovation and streamline production.

What Are Automotive Injection Molds?

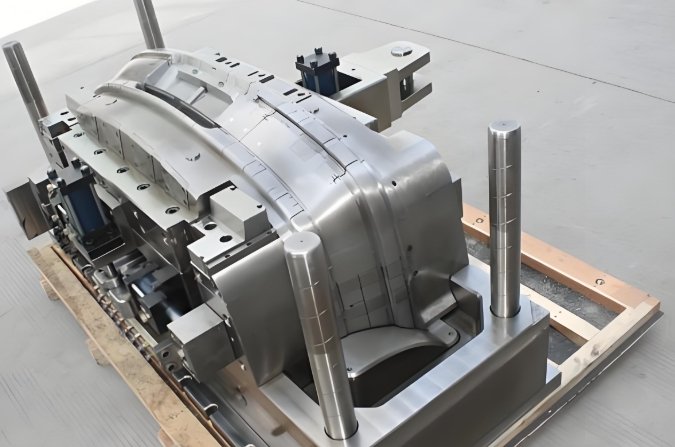

Automotive Injection Molds are tools used to create plastic car parts. They shape melted plastic into desired forms. Parts like dashboards, bumpers, and door panels come from these molds. A skilled Mold Maker ensures the molds perform well and last long.

Why Are Injection Molds Critical in Automotive Manufacturing?

1. Precision and Consistency

Injection molds produce identical parts. Every part meets precise dimensions.

2. High Efficiency

Once a mold is created, it can produce thousands of parts quickly.

3. Durability

High-quality molds withstand repeated use. This saves costs over time.

The Role of a Mold Maker in Automotive Injection Molds

1. Design Expertise

A Mold Maker designs molds for specific parts. Their expertise ensures the molds function perfectly.

2. Material Selection

The Mold Maker chooses strong materials for the molds. Steel and aluminum are common choices.

3. Problem Solving

They address challenges like complex part shapes or material compatibility.

Common Automotive Parts Made with Injection Molds

1. Exterior Components

- Bumpers

- Grills

- Fender liners

2. Interior Components

- Dashboards

- Door panels

- Center consoles

3. Under-the-Hood Components

- Engine covers

- Air ducts

- Battery housings

Key Steps in Creating Automotive Injection Molds

1. Understanding Requirements

The process begins with understanding the part’s design. Engineers work with the Mold Maker to finalize details.

2. Prototyping

Prototypes test the design before creating the mold. 3D printing often helps in this phase.

3. Machining the Mold

CNC machines carve the mold from metal blocks. This step ensures precision.

4. Polishing and Testing

The mold is polished for a smooth finish. Tests ensure it performs flawlessly.

Benefits of Using Injection Molds in the Automotive Industry

1. Cost-Effectiveness

Injection molds save money by producing large quantities of parts.

2. Speed

The injection process is quick, reducing production times.

3. Flexibility

Molds can create complex shapes.

4. Quality Assurance

Parts from injection molds are consistent and defect-free.

Innovations in Automotive Injection Molds

1. Lightweight Materials

Using lightweight plastics reduces vehicle weight.

2. Smart Molding Technologies

Sensors monitor and improve the injection process.

3. Sustainable Solutions

Recyclable plastics and eco-friendly methods are becoming popular.

Challenges in Automotive Injection Molding

1. Design Complexity

Intricate part designs make mold creation challenging.

2. Material Compatibility

Molds must handle different plastic materials.

3. High Initial Costs

Creating a mold is expensive. However, the long-term benefits outweigh the cost.

Choosing the Right Mold Maker for Automotive Applications

1. Experience Matters

Select a Mold Maker with automotive industry experience.

2. Advanced Tools

They should use cutting-edge technology for precision.

3. Customer Support

Good support ensures smooth collaboration.

Applications of Automotive Injection Molds

1. Electric Vehicles (EVs)

Molds create lightweight components for EVs.

2. Luxury Cars

High-end vehicles demand precise and elegant interior parts.

3. Mass Production Vehicles

Injection molds ensure quick and consistent production.

Future of Automotive Injection Molding

1. AI Integration

Artificial Intelligence improves mold design and monitoring.

2. Sustainable Practices

Eco-friendly solutions will shape the industry.

3. Customization

Injection molding will offer more personalized solutions.

Automotive Injection Molds are essential for modern car manufacturing. A skilled Mold Maker ensures the molds are precise and durable. These molds enable cost-effective, high-quality production. As technology advances, injection molding will continue to revolutionize the automotive industry.

Invest in the right molds and experts for long-term success. Choose a reliable Mold Maker to meet your automotive needs.