Electric vehicles (EVs) are shaping the future. Lightweight and durable parts are essential for EVs. Automotive Injection Molds make these parts efficiently. Skilled Mold Makers ensure precision and quality.

Why Injection Molds Matter in EVs

1. Lightweight Design

Injection molds create lightweight parts. This helps EVs improve range. Every kilogram saved makes a difference.

2. Cost Efficiency

Molded parts reduce production costs. Mass production becomes faster and cheaper.

3. Durability

Plastic components resist wear. They last longer under harsh conditions.

4. Complex Shapes

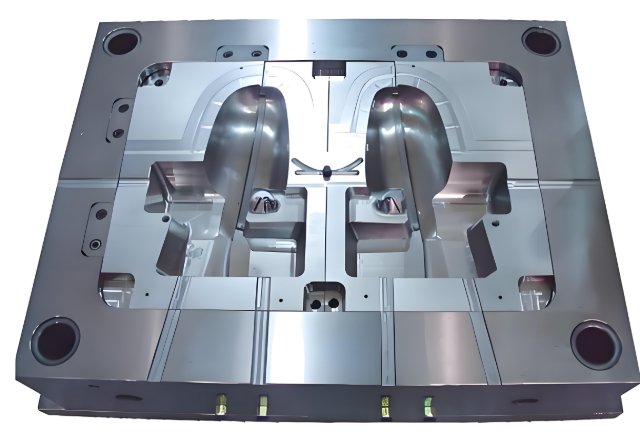

Molds handle intricate designs. EVs need custom components that fit perfectly.

Key EV Components Made with Injection Molds

1. Battery Cases

Injection molds produce strong battery enclosures. These cases protect batteries from damage.

2. Interior Panels

Dashboards, doors, and seats use molded parts. Lightweight panels reduce overall vehicle weight.

3. Exterior Components

Bumpers and trims are often injection molded. These parts are durable and visually appealing.

4. Electrical Housings

Plastic housings protect electronic parts. They insulate against heat and electrical interference.

The Role of Mold Makers in EV Production

1. Material Selection

Mold Makers choose materials carefully. They select plastics with strength and heat resistance.

2. Precision Engineering

Every EV part needs tight tolerances. Mold Makers use advanced tools for accuracy.

3. Sustainable Practices

Modern molds prioritize eco-friendly processes. This aligns with EV manufacturers’ goals.

4. Customization

Each EV brand has unique designs. Mold Makers tailor molds to specific needs.

Challenges in Injection Molding for EVs

1. High Temperatures

EV parts face heat challenges. Molds must handle plastics that withstand extreme temperatures.

2. Complex Designs

EV components often have intricate designs. Creating accurate molds for these parts takes expertise.

3. Cost Pressures

Initial mold creation can be expensive. However, mass production offsets these costs.

Innovations in EV Injection Molding

1. Reinforced Plastics

Combining plastics with fibers boosts strength. These materials are perfect for EV applications.

2. 3D Printing Prototypes

3D printing speeds up mold testing. It reduces development time significantly.

3. Smart Molds

Sensors monitor mold performance. This ensures consistent quality for EV parts.

4. AI-Driven Design

AI optimizes mold shapes. It finds ways to save material and improve efficiency.

Advantages of Injection Molds for EV Makers

1. Fast Production

Injection molding is quick. Thousands of parts are produced in a short time.

2. Consistency

Every part from the mold is identical. This ensures high quality in EVs.

3. Reduced Waste

Modern molds minimize material waste. This supports green manufacturing goals.

4. Adaptability

Molds can be adjusted for new designs. This is vital in the evolving EV market.

Applications of Injection Molds in EV Factories

1. Assembly Lines

Molded parts fit seamlessly into assembly lines. They ensure smooth operations.

2. Replacement Parts

Spare parts for EVs often use injection molds. They maintain the same quality as original parts.

3. Safety Features

Airbag housings and impact-resistant parts use molded plastics. These ensure safety in EVs.

Trends in Injection Molding for EVs

1. Sustainable Materials

Recycled plastics are gaining popularity. They align with EVs’ eco-friendly image.

2. Advanced Cooling Systems

New cooling methods speed up production. This boosts efficiency in EV factories.

3. Integration with AI

AI enhances mold design and monitoring. It predicts potential issues before they occur.

Future of EVs and Injection Molds

1. Improved Plastics

Stronger and lighter plastics are being developed. They will further enhance EV performance.

2. Automation in Molding

Robots will handle more tasks. This increases precision and speed in molding processes.

3. Greater Customization

Custom molds will allow unique EV designs. This supports branding and innovation.

Choosing the Right Mold Maker

1. Experience in EV Components

Select a Mold Maker with EV expertise. Their knowledge ensures the best results.

2. Advanced Technology

Modern tools improve mold accuracy. Choose providers with cutting-edge equipment.

3. Support and Service

Reliable Mold Makers offer ongoing support. They help update molds as needed.

Injection molds are vital for EV production. They make lightweight, durable, and cost-effective parts. Expert Mold Makers drive innovation in this field.

As EV demand grows, so does the need for advanced molds. Sustainable practices and cutting-edge technology ensure progress. Choosing the right Mold Maker ensures quality and success in the competitive EV market.

Injection molds will continue to shape the future of electric vehicles.