The automotive industry demands precision. Automotive Injection Molds play a critical role. These molds shape essential vehicle components. Skilled Mold Makers ensure every mold delivers quality. Innovation in mold design drives efficiency and performance.

The Importance of Automotive Injection Molds

1. Shaping the Industry

Injection molds create complex vehicle parts. They define quality and precision in production.

2. Ensuring Durability

Automotive components must withstand wear. Molds ensure strength in every part.

3. Reducing Costs

High-quality molds improve manufacturing efficiency. This reduces production expenses.

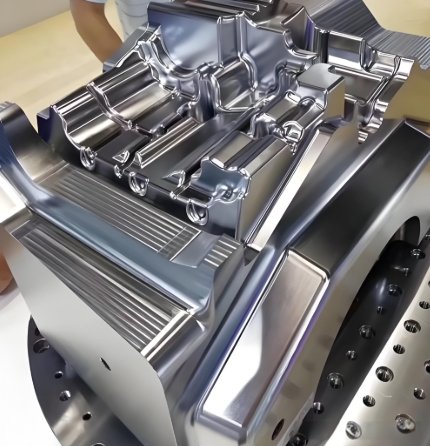

Key Features of Modern Automotive Injection Molds

1. Precision Engineering

Molds create parts with exact dimensions. Skilled Mold Makers use advanced tools.

2. Efficient Cooling Systems

Cooling channels improve cycle times. Faster cycles mean higher productivity.

3. Custom Designs

Every mold meets specific vehicle needs. This ensures compatibility and functionality.

4. Durable Materials

High-strength metals enhance mold life. They resist wear and ensure reliability.

The Role of the Mold Maker

1. Design Expertise

Mold Makers craft designs for efficiency. They combine innovation with practicality.

2. Material Selection

The right material ensures durability. Steel and aluminum are common choices.

3. Precision Manufacturing

Every detail matters in mold creation. Advanced machines ensure perfect results.

4. Continuous Improvement

Feedback helps refine mold performance. Mold Makers adapt to industry changes.

Types of Components Made with Injection Molds

1. Interior Panels

Molds create dashboards and door trims.

2. Engine Parts

Covers, housings, and mounts need precision.

3. Lighting Systems

Molds shape lenses and protective covers.

4. Exterior Features

Bumpers, grilles, and fenders require durability.

Challenges in Automotive Injection Mold Design

1. Complex Geometries

Vehicle parts have intricate designs. Molds must match every detail.

2. Material Compatibility

Molds must work with various plastics.

3. High Production Volumes

Durable molds handle repeated use.

4. Strict Standards

Automotive components must meet safety regulations.

Innovations in Mold Design

1. 3D Modeling

Digital tools improve design accuracy.

2. Advanced Materials

New alloys enhance mold strength.

3. Smart Monitoring Systems

Sensors track mold performance in real-time.

4. Sustainable Practices

Recycled materials reduce environmental impact.

Benefits of High-Quality Automotive Injection Molds

1. Consistent Quality

Precision molds ensure reliable components.

2. Cost Efficiency

Durable molds save money on replacements.

3. Faster Production

Efficient designs speed up manufacturing.

4. Reduced Waste

Better molds mean fewer rejected parts.

Steps in Creating an Injection Mold

1. Concept Development

Understand the part’s purpose and design.

2. Material Selection

Choose the best material for the mold.

3. Prototyping

Create and test a prototype mold.

4. Final Manufacturing

Use advanced machines for precision.

5. Testing and Validation

Ensure the mold meets all requirements.

Future Trends in Automotive Injection Molds

1. AI-Driven Design

Artificial intelligence enhances mold accuracy.

2. Sustainable Materials

Biodegradable plastics are gaining traction.

3. Robotic Assistance

Robots streamline mold manufacturing.

4. Smart Mold Systems

Embedded sensors monitor mold health.

Applications of Injection Molds in Automobiles

1. Safety Systems

Molds shape airbags and seatbelt components.

2. Electrical Systems

Battery housings and connectors rely on molds.

3. Fuel Systems

Molds create tanks and fuel line components.

4. Aesthetic Features

Interior trims and decorative panels use molds.

Automotive Injection Molds are vital in vehicle production. Skilled Mold Makers craft them with precision. Advanced designs improve quality and efficiency. As technology advances, molds will become even more innovative. Durable, efficient molds shape the future of automotive manufacturing. Investing in quality molds ensures long-term success.