High-performance automotive parts require precision. Automotive Injection Molds deliver this precision. Expert Mold Makers ensure quality. These molds meet strict requirements. They produce durable, efficient, and complex components.

Why High-Performance Parts Need Precision

1. Exact Fit

High-performance parts demand accurate dimensions.

2. Durability

Molds produce parts that withstand stress.

3. Lightweight Construction

Precision molds reduce unnecessary weight.

4. Complex Designs

Molds create intricate shapes with ease.

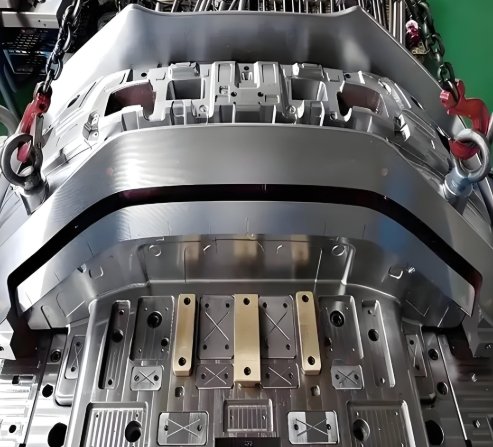

Key Features of Automotive Injection Molds

1. High-Temperature Resistance

Molds handle tough materials like carbon fiber.

2. Smooth Surface Finish

Molds ensure parts look and perform flawlessly.

3. Durability Under Pressure

They produce components for extreme conditions.

4. Advanced Cooling Systems

Efficient cooling speeds up production.

Role of the Mold Maker

1. Material Selection

Mold Makers choose strong, durable materials.

2. Design Expertise

They create precise designs for each part.

3. Quality Control

Every mold undergoes rigorous testing.

4. Use of Advanced Tools

CNC and 3D printing ensure accuracy.

Applications of High-Performance Molds

1. Engine Components

Molds craft durable engine covers.

2. Transmission Parts

Injection molds ensure smooth operation.

3. Suspension Systems

Precision parts enhance vehicle stability.

4. Aerodynamic Features

Molds shape lightweight and efficient panels.

Innovations in High-Performance Mold Design

1. Multi-Material Molds

Combine different materials for stronger parts.

2. Hot Runner Systems

Reduce waste and improve efficiency.

3. Smart Molds

Sensors monitor molding in real time.

4. Eco-Friendly Solutions

Green molds reduce production waste.

Steps in Producing High-Performance Molds

1. Design Phase

Create digital models of the mold.

2. Prototype Testing

Build and test a sample mold.

3. Material Selection

Choose materials suited for high-performance parts.

4. Precision Machining

Use advanced tools to build the mold.

5. Final Testing

Ensure the mold meets performance standards.

Benefits of Using Injection Molds

1. Cost Efficiency

Molds reduce material waste.

2. Speed

They allow faster production times.

3. Accuracy

Molds produce consistent, reliable parts.

4. Customization

They meet specific performance needs.

Challenges in High-Performance Molding

1. Material Complexity

High-performance parts need advanced materials.

2. Design Accuracy

Precision is crucial for performance.

3. Cost of Innovation

Advanced molds require significant investment.

4. Production Scalability

Meeting large-scale demand can be challenging.

Trends in High-Performance Automotive Molds

1. Lightweight Materials

Focus on reducing vehicle weight.

2. Sustainability

Eco-friendly practices are on the rise.

3. Automation

Robots streamline mold production.

4. AI Integration

Artificial intelligence enhances mold accuracy.

Future of High-Performance Molding

1. Eco-Friendly Molds

Sustainability will lead innovation.

2. Advanced Materials

Stronger, lighter materials will emerge.

3. Smart Manufacturing

Real-time monitoring will improve efficiency.

4. Customization at Scale

Molds will adapt to diverse needs.

Automotive Injection Molds are essential for high-performance parts. Skilled Mold Makers ensure precision and quality. These molds meet strict automotive standards. With continuous innovation, they are shaping the future of high-performance vehicles.