The automotive industry faces new challenges. Lightweight designs, precision, and sustainability are vital. Automotive Injection Molds address these needs. Expert Mold Makers deliver innovative solutions. This article explores how they overcome these challenges.

Modern Automotive Challenges

1. Demand for Lightweight Parts

Cars need lighter parts to improve fuel efficiency.

2. Enhanced Safety Standards

Every component must meet strict safety requirements.

3. Sustainable Manufacturing

Eco-friendly materials and processes are in demand.

4. Complex Designs

Advanced vehicle designs require intricate parts.

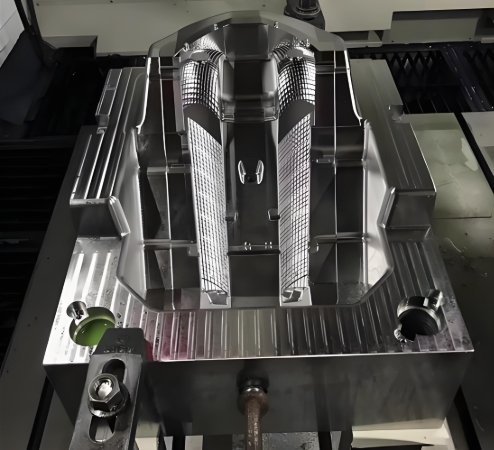

Role of Automotive Injection Molds

1. Lightweight Components

Molds create strong, lightweight parts.

2. Precision Engineering

They ensure accurate dimensions for every part.

3. Durable Solutions

Parts last longer, reducing maintenance costs.

4. Custom Designs

Molds allow unique shapes for each model.

Key Applications of Injection Molds

1. Engine Components

Molds produce precise engine covers and housings.

2. Interior Parts

They create dashboards, consoles, and trims.

3. Exterior Features

Molds shape bumpers, grilles, and panels.

4. Lighting Systems

Molds ensure accurate and durable light housings.

How Mold Makers Ensure Quality

1. Material Selection

Mold Makers choose high-grade materials.

2. Advanced Tools

They use cutting-edge machines for better results.

3. Detailed Prototypes

Prototypes verify designs before mass production.

4. Strict Testing

Parts undergo rigorous tests for strength and accuracy.

Advantages of Injection Mold Technology

1. High Efficiency

Molds speed up production times.

2. Cost-Effective Solutions

They lower production costs significantly.

3. Waste Reduction

Precision minimizes material waste.

4. Versatility

Molds create parts for diverse automotive needs.

Challenges in Injection Molding

1. Material Compatibility

Some designs need specialized materials.

2. Complex Part Shapes

Intricate designs require expert craftsmanship.

3. Cost of Advanced Molds

High-quality molds can be expensive.

4. Evolving Standards

Automotive regulations change frequently.

Innovations in Automotive Injection Molds

1. Multi-Material Molding

Combines different materials in one part.

2. Lightweight Materials

Focus on carbon fiber and reinforced plastics.

3. Recyclable Plastics

Eco-friendly materials reduce environmental impact.

4. Smart Manufacturing

Automation increases accuracy and efficiency.

Steps in Mold Development

1. Concept Design

Sketch the part and its dimensions.

2. 3D Modeling

Digital models improve accuracy.

3. Prototype Testing

Create and test sample molds.

4. Final Production

Use the mold for large-scale manufacturing.

Applications in Electric Vehicles

1. Battery Housings

Molds produce strong, lightweight battery covers.

2. Cooling Systems

Injection molds create parts for thermal management.

3. Lightweight Frames

Reduce overall weight with precision-molded frames.

4. Custom Interiors

Unique designs for EV-specific interiors.

Future Trends

1. Sustainable Solutions

Focus on green materials and processes.

2. Faster Production

Automation will cut production times further.

3. Smarter Parts

Molds will integrate sensors into components.

4. Higher Precision

Standards for accuracy will continue to rise.

Automotive Injection Molds are crucial for solving modern challenges. Expert Mold Makers deliver precision, efficiency, and innovation. As the industry evolves, injection molds will remain key to creating durable, sustainable, and advanced automotive parts.