Modern vehicles rely on precision. Automotive Injection Molds play a key role. Expert Mold Makers create molds that define quality. These molds produce intricate parts efficiently. The process combines science, engineering, and innovation. It transforms raw materials into essential automotive components.

The Basics of Injection Molding

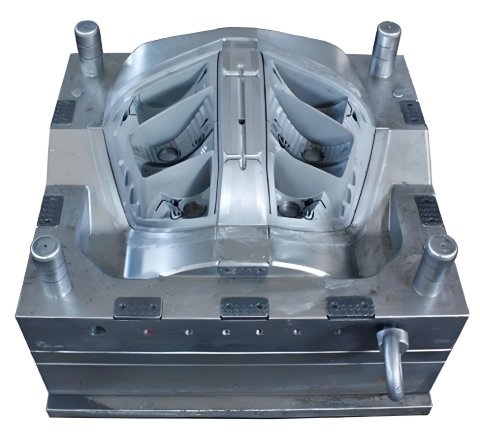

1. What is Injection Molding?

Injection molding shapes plastic using heat and pressure.

2. Core Components of the Process

- Mold Cavity: Shapes the part.

- Injection Unit: Melts and injects plastic.

- Clamping Unit: Holds the mold during production.

3. Materials Used

Common plastics include polypropylene, ABS, and nylon.

4. Cycle Process

- Plastic melts.

- Injection fills the mold.

- Cooling solidifies the part.

- Ejection removes the part.

The Role of Automotive Injection Molds

1. Precision in Design

Molds deliver accurate shapes and dimensions.

2. High Repeatability

Each part matches the last one perfectly.

3. Customization Capabilities

Molds enable unique, complex designs.

4. Durability

Quality molds last through extensive production runs.

Key Automotive Applications

1. Interior Components

- Dashboard panels

- Air vents

- Seat adjusters

2. Exterior Parts

- Bumpers

- Grilles

- Door trims

3. Functional Features

- Engine covers

- Battery casings

- Air intake manifolds

4. Lighting Elements

- Headlight housings

- Taillight covers

Science Behind Mold Creation

1. Material Selection

- Choose materials based on strength and temperature tolerance.

2. Computer-Aided Design (CAD)

- Software designs molds with extreme precision.

3. Flow Analysis

- Simulations optimize material flow.

4. Machining Techniques

- CNC machines carve molds to perfection.

5. Surface Finishing

- Polishing ensures smooth, defect-free surfaces.

Importance of Skilled Mold Makers

1. Experience in Precision

Mold Makers ensure molds meet strict standards.

2. Problem Solving

They address challenges like warping or shrinkage.

3. Custom Solutions

They create molds for unique automotive needs.

4. Efficiency Focus

Expertise reduces production times.

5. Quality Assurance

Mold Makers inspect every detail.

Challenges in Automotive Injection Molding

1. Material Defects

Low-quality plastics affect final products.

2. Complex Geometries

Detailed designs increase mold complexity.

3. Cooling System Efficiency

Poor cooling causes defects.

4. Tool Wear and Tear

Frequent use leads to mold damage.

5. Cost Management

High-quality molds require investment.

Innovations in Injection Molding

1. 3D Printing for Prototyping

Speeds up design validation.

2. Advanced Materials

New plastics improve durability and aesthetics.

3. Robotics and Automation

Boosts speed and consistency.

4. Real-Time Monitoring

Sensors ensure quality during production.

5. Eco-Friendly Solutions

Recycled plastics reduce waste.

Benefits of Automotive Injection Molds

1. Mass Production

Produce thousands of parts quickly.

2. High Accuracy

Parts fit perfectly every time.

3. Cost Efficiency

Large-scale production lowers costs.

4. Versatility

Molds create a variety of automotive parts.

5. Longevity

Durable molds support long-term use.

Future of Automotive Injection Molding

1. Sustainability Focus

Molds will support greener materials.

2. Smart Manufacturing

AI and IoT will optimize processes.

3. Customizable Designs

Personalization will drive innovation.

4. Integration with Electric Vehicles

Molds will adapt to EV-specific components.

5. Global Collaboration

Mold Makers worldwide will share expertise.

The science behind Automotive Injection Molds drives the automotive industry forward. Skilled Mold Makers bring precision and innovation to every project. From interior details to functional parts, injection molds shape the future of vehicle manufacturing. As technology advances, these molds will continue to set new standards.