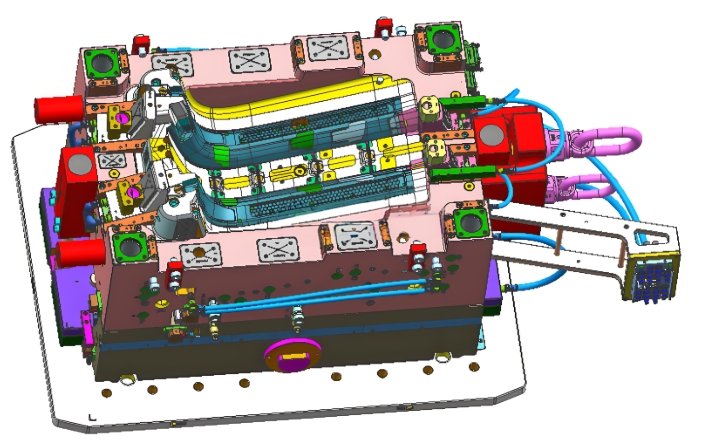

The automotive industry depends on Automotive Injection Molds. These molds shape car parts with precision. Skilled Mold Makers create solutions for various applications. They ensure durability, design, and efficiency. Let’s explore the innovative applications of injection molds in the automotive sector.

Molding Interior Components

1. Dashboard Panels

Injection molds create smooth dashboard panels. They provide texture and design flexibility.

2. Door Panels

Plastic door panels offer lightweight durability. Molds allow intricate patterns and shapes.

3. Control Knobs

Small knobs need precise molds. These components improve the vehicle’s functionality.

Exterior Applications

1. Bumpers

Injection molds produce impact-resistant bumpers. Lightweight designs reduce vehicle weight.

2. Grilles

Molded grilles combine style and function. They also improve airflow efficiency.

3. Mirror Housings

Mirror housings require strong materials. Injection molds ensure high durability.

Functional Under-the-Hood Parts

1. Engine Covers

Plastic engine covers replace metal ones. Molds shape heat-resistant materials for these parts.

2. Air Intakes

Precision molding ensures smooth airflow paths. This improves engine performance.

3. Battery Housings

EV batteries need lightweight, protective housings. Molds meet this demand.

Lighting Applications

1. Headlight Lenses

Injection molds produce clear, durable lenses. These improve visibility and aesthetics.

2. Tail Lights

Custom tail light designs enhance vehicle appearance. Molds make these designs possible.

Advanced Seating Systems

1. Plastic Frames

Injection molds create lightweight seat frames. These frames maintain strength and durability.

2. Adjustable Mechanisms

Small, molded components power seat adjustments.

Advantages of Automotive Injection Molds

1. Weight Reduction

Plastic parts replace heavy metal ones. This improves fuel efficiency.

2. Cost Efficiency

Mass production lowers manufacturing costs.

3. Design Flexibility

Molds allow creative and custom designs.

4. Durability

Molded parts resist heat, impact, and chemicals.

Role of Skilled Mold Makers

1. Precision Designs

Mold Makers ensure accurate mold designs. Precision reduces material waste.

2. Material Selection

They choose materials that meet automotive standards. Heat and impact resistance are key factors.

3. Prototype Development

Prototypes validate designs before production.

4. Innovation

Experienced Mold Makers use advanced tools. They integrate the latest molding technologies.

Eco-Friendly Innovations

1. Recycled Materials

Molds process recycled plastics into car parts.

2. Biodegradable Plastics

Future designs focus on biodegradable materials.

3. Energy-Efficient Molding

Modern machines reduce energy consumption.

Custom Molded Solutions

1. Luxury Trims

Molded trims add elegance to luxury vehicles.

2. Custom Logos

Automotive brands use custom-molded logos.

3. Unique Aesthetic Features

Molds allow intricate designs for unique appearances.

Challenges in Injection Mold Applications

1. Complex Geometries

Some designs are hard to mold. Skilled Mold Makers solve these challenges.

2. Material Limitations

Not all plastics meet automotive requirements.

3. Cost of High-Precision Molds

Creating high-quality molds can be expensive.

Future Trends

1. Smart Materials

Plastics with embedded sensors are becoming popular.

2. Fully Automated Molding

Automation reduces errors and increases efficiency.

3. Sustainability Focus

Recyclable and eco-friendly materials are the future.

4. Digital Twin Technology

Simulations optimize mold designs before production.

Automotive Injection Molds drive innovation in the automotive industry. Skilled Mold Makers create precision parts for every application. These molds reduce costs, improve designs, and ensure sustainability. From interiors to under-the-hood components, injection molding leads the way. The future promises even more exciting advancements.