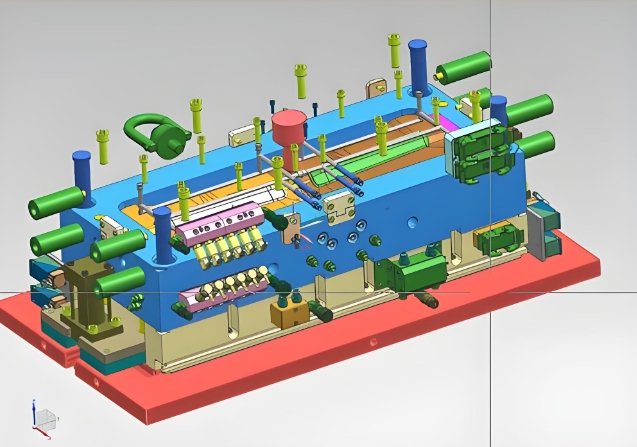

The automotive industry thrives on precision. High-quality Automotive Injection Molds make this possible. Skilled Mold Makers create durable molds for all car parts. These molds shape plastic into functional and aesthetic components. Let’s explore how their expertise drives automotive excellence.

Interior Automotive Components

1. Dashboard Panels

Injection molds ensure perfect dashboard designs. They add strength and texture.

2. Air Vents

Molds create intricate air vent designs. These allow proper airflow inside vehicles.

3. Door Panels

Plastic door panels are lightweight. Molds make custom shapes and sizes possible.

Exterior Components

1. Bumpers

Bumpers need high durability. Automotive Injection Molds help achieve that.

2. Grilles

Molded grilles improve car design and performance.

3. Mirror Housings

Molds ensure strong and sleek mirror covers.

Functional Components

1. Engine Covers

Plastic engine covers reduce weight. Mold Makers ensure durability.

2. Battery Housings

For electric vehicles, battery protection is critical. Molds provide safe housings.

3. Air Intakes

Molded air intakes improve engine efficiency.

Lighting Systems

1. Headlight Lenses

Injection molds create clear and durable lenses. These are essential for visibility.

2. Tail Lights

Custom tail lights enhance vehicle aesthetics. Molds allow endless design options.

Seating Systems

1. Plastic Frames

Lightweight frames reduce car weight. Molds ensure structural integrity.

2. Adjustment Mechanisms

Molded components enable seat adjustments.

Advantages of Automotive Injection Molds

1. Lightweight Solutions

Plastic parts reduce overall car weight.

2. Cost-Effective Production

Molds lower manufacturing costs for mass production.

3. Custom Designs

Mold Makers allow innovative designs.

4. Durability

Molded parts resist impact, heat, and chemicals.

The Role of Expert Mold Makers

1. Design Precision

Mold Makers craft precise molds. This improves part accuracy.

2. Material Selection

They choose the best materials for strength and safety.

3. Prototyping

Prototypes validate mold designs before production.

4. Innovation

Advanced tools help Mold Makers push design limits.

Challenges in Injection Mold Applications

1. Complex Shapes

Some designs are hard to mold. Skilled Mold Makers solve these challenges.

2. Material Compatibility

Not all plastics meet automotive needs.

3. High-Precision Costs

Creating precise molds can be expensive.

Eco-Friendly Molding

1. Recycled Plastics

Molds use recycled materials for sustainability.

2. Biodegradable Plastics

Future molds will focus on eco-friendly options.

3. Energy Efficiency

Modern molding machines use less energy.

Future of Automotive Injection Molds

1. Smart Materials

Materials with sensors improve functionality.

2. Automation

Automated molding increases production speed.

3. Digital Prototypes

Simulations test designs before production.

4. Eco-Focused Designs

Sustainability will drive new mold innovations.

Why Choose Experts?

1. Industry Knowledge

Experienced Mold Makers understand automotive needs.

2. Custom Solutions

They deliver tailored molds for specific designs.

3. Quality Assurance

Experts ensure molds meet high standards.

4. Timely Delivery

Experienced teams meet tight deadlines.

The automotive industry relies on Automotive Injection Molds for precision and innovation. Expert Mold Makers craft molds that shape the future of automotive design. From interiors to engines, molds drive efficiency, durability, and style. Choosing experienced professionals ensures excellence at every step.