The automotive industry is evolving. Cars are becoming smarter, safer, and more fuel-efficient. Automotive Injection Molds are essential to this transformation. These molds are used to create innovative parts for next-generation vehicles. Mold Makers are driving this progress with advanced techniques and materials. In this article, we explore how Automotive Injection Molds are shaping the future of the automotive industry.

The Rise of Next-Generation Vehicles

1. Electric Vehicles (EVs)

Electric vehicles are becoming more popular. They need lightweight, durable parts. Automotive Injection Molds help create these parts.

2. Autonomous Vehicles

Autonomous cars require advanced sensors and electronics. Molds help produce these components with high precision.

3. Connected Cars

Cars today are smarter. They communicate with other vehicles and systems. Injection molds create the parts for these technologies.

Importance of Automotive Injection Molds in Next-Gen Vehicles

1. Precision Manufacturing

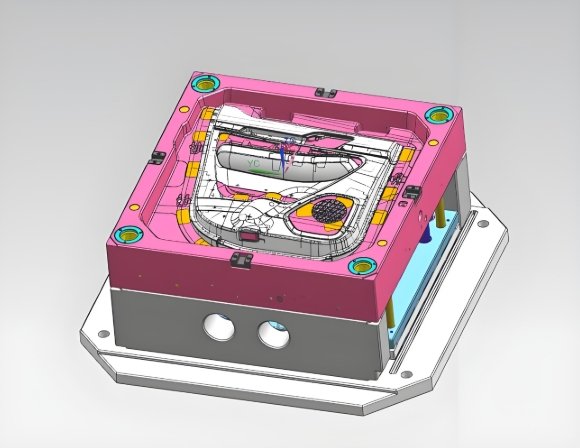

Automotive Injection Molds allow for high-precision manufacturing. Parts must be made with exact tolerances.

2. Material Efficiency

Molding reduces material waste. Advanced materials are used efficiently in Automotive Injection Molds.

3. Complex Part Design

Next-gen vehicles require complex parts. Automotive Injection Molds make it possible to produce these parts with ease.

Key Technologies in Automotive Injection Molds

1. Gas-Assisted Injection Molding

Gas-assisted molding uses gas to create hollow parts. This reduces weight without losing strength.

2. Thin-Wall Molding

Thin-wall molding is crucial for making lightweight parts. It minimizes the material needed while maintaining strength.

3. Multi-Shot Molding

Multi-shot molding involves using more than one material in a single mold. It’s ideal for producing parts with multiple features in one go.

Materials for Next-Gen Automotive Parts

1. High-Performance Plastics

Plastics like polycarbonate and PEEK are used for next-gen vehicles. These materials are strong, lightweight, and versatile. Mold Makers use advanced techniques to mold these materials accurately.

2. Composite Materials

Carbon fiber and fiberglass composites are lightweight and durable. Automotive Injection Molds can shape these materials into complex parts for high-performance vehicles.

3. Metals and Alloys

Metals like aluminum are essential for structural parts. Molds for these metals need to be precise and durable.

Applications in Electric and Hybrid Vehicles

1. Battery Housings

Electric vehicles need battery housings that are lightweight and strong. Automotive Injection Molds create these parts efficiently.

2. Cooling Systems

EVs and hybrids require advanced cooling systems. Molds are used to create intricate components for these systems.

3. Structural Parts

Lightweight frames and components are needed for EVs. Injection molding makes these parts strong yet light.

Molds for Autonomous Vehicle Components

1. Sensor Housings

Autonomous vehicles need precise sensor housings. Automotive Injection Molds are used to create these critical components.

2. Interior Panels

Next-gen vehicles often have futuristic interior designs. Molds help produce sleek, durable panels with advanced materials.

3. Electronic Components

Autonomous cars rely heavily on electronics. Automotive Injection Molds are crucial in shaping these complex parts.

The Role of Mold Makers in Next-Gen Vehicles

1. Innovative Designs

Mold Makers are responsible for designing molds that can create the complex parts needed for next-gen vehicles.

2. Material Expertise

They understand the properties of various materials. This ensures that the right material is chosen for each part.

3. Customization

Mold Makers can customize molds for specific vehicle models. This ensures that each part fits perfectly and functions efficiently.

Future Trends in Automotive Injection Molding

1. Smart Molding

Smart molding techniques will allow molds to monitor themselves. This can reduce waste and improve efficiency.

2. 3D Printing Integration

3D printing may be combined with Automotive Injection Molds. This could speed up prototyping and reduce costs.

3. Sustainable Materials

The demand for eco-friendly materials is growing. Mold Makers are finding new ways to use sustainable materials in molding processes.

Challenges in Automotive Injection Molding

1. Material Selection

Choosing the right material is critical. It must meet the performance standards of next-gen vehicles.

2. Mold Complexity

As vehicles become more advanced, the molds must be more complex. This increases production time and costs.

3. Cost Efficiency

While Automotive Injection Molds are efficient, the cost of advanced molds and materials can be high.

Benefits of Automotive Injection Molds for Next-Gen Vehicles

1. Reduced Weight

Injection molding helps reduce the weight of vehicle parts. Lighter vehicles consume less energy.

2. Faster Production

Injection molding allows for faster production of high-quality parts.

3. High Precision

Molding ensures that parts are made with high precision. This is essential for next-gen vehicle performance.

Automotive Injection Molds are transforming the production of next-generation vehicles. From electric cars to autonomous vehicles, injection molding is helping to create innovative, lightweight, and efficient components. Mold Makers play a vital role in this process, providing the expertise needed to design and create molds for these advanced parts. As the automotive industry continues to evolve, Automotive Injection Molds will remain at the heart of vehicle production.