The automotive industry is demanding more precision than ever before. Automotive Injection Molds play a vital role in shaping the future of vehicle manufacturing. These molds create complex parts that must meet strict standards. Mold Makers use precision engineering techniques to ensure that parts are both durable and high-performing. This article will explore the importance of precision engineering in Automotive Injection Molds.

The Need for Precision in Automotive Parts

1. High Performance

Automotive parts must perform well under extreme conditions. Automotive Injection Molds ensure that each part is made to withstand these conditions.

2. Tight Tolerances

Automotive components need to fit perfectly together. Precision molding ensures that every part meets tight tolerances.

3. Safety Standards

Safety is critical in automotive design. Mold Makers must ensure that molded parts meet safety standards to protect drivers and passengers.

Role of Automotive Injection Molds in Automotive Manufacturing

1. Complex Part Design

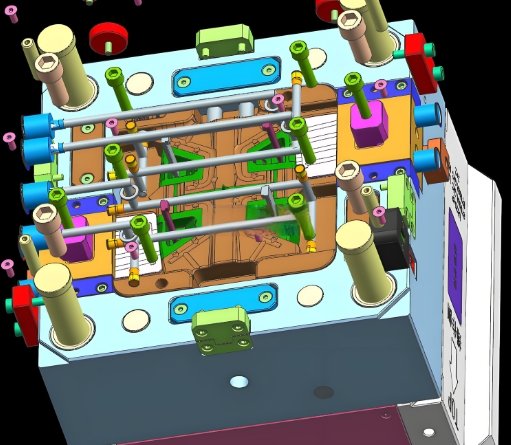

Modern vehicles have intricate designs. Automotive Injection Molds are used to produce complex parts with high precision.

2. Cost-Effective Production

Injection molding allows manufacturers to produce parts quickly and at a lower cost. Precision engineering reduces waste, making the process more efficient.

3. Material Versatility

Injection molding can work with various materials. Whether it’s metal, plastic, or composite, Automotive Injection Molds can handle it.

Mold Maker Expertise in Precision Design

1. Material Knowledge

Mold Makers are experts in material science. They choose the best materials for each application, ensuring long-lasting and reliable parts.

2. Tooling Mastery

Precision tooling is crucial in injection molding. Mold Makers use advanced tools to create molds with exact specifications.

3. Advanced Technology

Mold Makers use advanced technologies like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). These tools allow for highly accurate mold designs.

Precision Engineering in Molding Processes

1. 3D Printing for Prototyping

Before full-scale production, 3D printing is used to create prototypes. This allows for testing and refining the design.

2. Multi-Shot Molding

Multi-shot molding uses more than one material in the same mold. This technique allows for complex parts that perform multiple functions.

3. Gas-Assisted Injection Molding

Gas-assisted injection molding is used for creating lightweight but strong parts. It uses gas to form cavities inside the part, reducing weight without compromising strength.

Challenges in Precision Engineering

1. Complex Geometry

Modern vehicle designs have complex geometries. Creating molds for these parts requires advanced engineering techniques.

2. Material Selection

Selecting the right material for each part is critical. Some parts need to be lightweight, while others must be more durable. Mold Makers carefully select materials to meet these demands.

3. Tool Wear and Maintenance

The precision of the molds depends on how well they are maintained. Regular maintenance is required to ensure that molds remain accurate and functional.

Benefits of Automotive Injection Molds in Precision Engineering

1. High Accuracy

Injection molding provides high precision, ensuring that each part fits together seamlessly.

2. Cost Efficiency

Precision engineering in molds reduces material waste and production time, making it a cost-effective solution.

3. Durability

Parts produced using Automotive Injection Molds are designed to last. The materials and processes used ensure longevity and reliability.

Key Applications of Precision Molds in Automotive Industry

1. Engine Components

Engine components require high precision. Automotive Injection Molds are used to produce these complex and durable parts.

2. Interior Components

Parts like dashboards, door panels, and seats need to be precisely molded for safety and comfort.

3. Lighting Systems

Lighting components like headlights and tail lights require high accuracy to ensure they function correctly. Automotive Injection Molds help create these parts.

How Precision Engineering Shapes Future Automotive Designs

1. Electric Vehicles (EVs)

EVs require lightweight, high-performance components. Automotive Injection Molds are used to create these advanced parts with high precision.

2. Autonomous Vehicles

Autonomous vehicles rely on advanced sensor systems. Molding processes ensure that these components are both precise and durable.

3. Sustainable Vehicles

With the demand for sustainable transportation, precision molds are crucial in creating eco-friendly, lightweight parts that reduce energy consumption.

Mold Maker Innovations in Automotive Injection Molding

1. Smart Molds

The future of precision engineering in molds is smart technology. Mold Makers are developing molds that monitor and adjust in real-time to improve production efficiency.

2. Hybrid Materials

Using a combination of materials can improve part performance. Hybrid materials are becoming more common in automotive injection molding.

3. Additive Manufacturing

The integration of additive manufacturing into traditional molding processes is enhancing the precision of automotive parts.

The Future of Automotive Injection Molds

1. Sustainability

As the automotive industry moves towards greener solutions, precision molds will be made from sustainable materials and will produce eco-friendly parts.

2. Customization

With the rise of personalized vehicles, Mold Makers will create molds that allow for more customized parts.

3. Faster Production Times

Advances in mold-making technologies will continue to shorten production times. Faster production will allow manufacturers to meet the increasing demand for next-gen vehicles.

Precision engineering in Automotive Injection Molds is transforming vehicle manufacturing. Mold Makers play a critical role in this transformation by using advanced techniques to create high-precision molds. The result is high-quality, durable automotive parts that meet the stringent demands of modern vehicles. With new technologies and materials, the future of Automotive Injection Molds looks even more promising, as they continue to shape the cars of tomorrow.