The demand for high-end vehicles is growing. These cars require precise, durable, and reliable parts. Automotive Injection Molds play a key role in creating these components. Skilled Mold Makers ensure every mold meets exacting standards. This article explores the techniques, materials, and benefits of injection molds for premium vehicles.

Importance of Automotive Injection Molds

Precision Manufacturing

High-end vehicles demand precision. Automotive Injection Molds ensure components fit perfectly. Even minor errors are unacceptable.

Durability

Premium cars require long-lasting parts. High-quality molds produce components that endure. This enhances the vehicle’s performance.

Customization

Luxury vehicles often feature unique designs. Injection molds allow for creative and complex shapes.

Role of the Mold Maker

Expert Design

A Mold Maker creates detailed designs. These designs ensure molds meet exact specifications.

Material Selection

Mold makers choose the best materials for strength and reliability. Their expertise ensures quality results.

Prototyping

Before mass production, molds are tested. Prototyping eliminates design flaws.

Maintenance

Molds require regular upkeep. Mold Makers repair and maintain molds to ensure consistent quality.

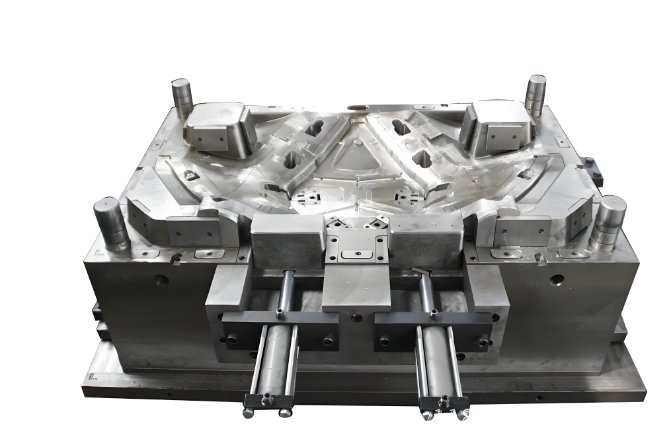

Key Features of High-End Vehicle Molds

1. Precision Engineering

Molds for luxury cars are highly detailed. They require exact dimensions and perfect finishes.

2. Advanced Materials

Premium molds use high-strength steel or aluminum. These materials withstand intense production cycles.

3. Complex Designs

Luxury cars feature intricate components. Molds must handle these complexities without errors.

4. Longevity

Molds for high-end vehicles last longer. This reduces downtime and production costs.

5. Eco-Friendly Options

Many molds now support sustainable manufacturing. They use recycled materials and minimize waste.

Applications of Automotive Injection Molds

1. Interior Components

Molds create dashboards, consoles, and trim. These parts need smooth finishes and tight tolerances.

2. Exterior Components

Bumpers, grilles, and panels are made with injection molds. They require durability and flawless surfaces.

3. Lighting Systems

Headlights and tail lights depend on precision molds. Clear, defect-free lenses are critical.

4. Engine Components

Molds produce heat-resistant parts like engine covers. They ensure performance and safety.

5. EV Components

Electric vehicles use lightweight, injection-molded parts. These include battery casings and motor housings.

Advanced Mold-Making Techniques

1. Hot Runner Systems

These systems improve material flow. They reduce waste and enhance part quality.

2. Multi-Cavity Molds

Multi-cavity molds increase production efficiency. They create multiple parts in a single cycle.

3. Overmolding

This technique combines different materials. It’s perfect for parts with soft-touch surfaces.

4. Gas-Assisted Molding

Gas-assisted molding creates hollow parts. It’s ideal for lightweight components.

5. Smart Molds

Smart molds feature built-in sensors. They monitor temperature and pressure for better results.

Challenges in Designing Molds for High-End Vehicles

1. Complexity of Designs

Luxury vehicles require intricate components. Molds must handle these complexities without errors.

2. Material Compatibility

Different materials behave differently. Molds must match the material’s properties.

3. Tight Tolerances

High-end parts demand extreme precision. Small errors can lead to big problems.

4. Cost of Production

Creating premium molds is expensive. However, they ensure long-term savings and quality.

5. Sustainability Goals

The auto industry is shifting toward eco-friendly production. Molds must adapt to these changes.

Benefits of Using Injection Molds for Luxury Cars

1. Cost Efficiency

Although expensive initially, injection molds save money in the long run. They enable mass production at lower costs.

2. Design Flexibility

Injection molds allow for unique and complex designs. This supports customization in luxury vehicles.

3. Enhanced Quality

High-quality molds produce flawless parts. This improves the vehicle’s overall appearance and performance.

4. Faster Production

Modern molds enable rapid manufacturing. This reduces lead times and boosts efficiency.

5. Environmental Benefits

Eco-friendly molds minimize waste and use recycled materials.

Future Trends in Automotive Injection Molding

1. Digital Integration

Advanced software improves mold design. It ensures accuracy and reduces errors.

2. Sustainable Practices

Mold makers are adopting greener methods. This includes using eco-friendly materials and reducing waste.

3. Lightweight Materials

The demand for lighter vehicles is growing. Molds must accommodate lightweight, durable materials.

4. Global Collaboration

Mold makers are working with international teams. This ensures global standards are met.

5. AI and Automation

Artificial intelligence streamlines mold design and production. It enhances precision and efficiency.

Automotive Injection Molds are crucial for high-end vehicle manufacturing. They ensure precision, durability, and customization. Skilled Mold Makers play a vital role in maintaining high standards. Advanced techniques and materials continue to push the boundaries of mold design. As the industry evolves, so do the standards and practices of injection molding. These molds are the backbone of luxury vehicle production. They set the stage for innovation, quality, and sustainability.