Insert molding is a key process in medical injection molding. It involves molding plastic around a metal or plastic insert. This creates strong and durable medical devices. Mold makers use this method to improve precision and efficiency.

What is Insert Molding?

1. Definition

Insert molding is a process where a pre-made insert is placed in a mold. Plastic is then injected around it.

2. How It Works

The insert is carefully positioned inside the mold. Then, molten plastic flows around it, bonding the parts together.

3. Why Insert Molding Matters

It reduces assembly steps, increases strength, and improves device reliability.

Benefits of Insert Molding in Medical Devices

1. Stronger Bonding

Plastic and inserts bond tightly. This prevents part separation.

2. Fewer Assembly Steps

No need for screws, glue, or welding. This speeds up production.

3. Improved Durability

The insert adds strength to the final part.

4. Higher Precision

Mold makers create detailed molds for accuracy.

5. Lightweight Parts

Plastic replaces heavy metal components.

6. Cost Savings

Fewer assembly steps mean lower labor costs.

Common Applications of Insert Molding in Medical Injection Molding

1. Surgical Instruments

Metal inserts improve grip and durability.

2. Implantable Devices

Insert molding secures electronic components in implants.

3. Catheters and Tubing

Plastic molds around connectors for leak-proof seals.

4. Diagnostic Equipment

Sensors and wiring are enclosed in durable plastic casings.

5. Medical Device Housings

Insert molding protects delicate electronic parts.

6. Drug Delivery Systems

Plastic components securely hold medication inserts.

Step-by-Step Insert Molding Process

1. Designing the Mold

Mold makers create precise molds for each insert.

2. Selecting the Insert

Metal, plastic, or electronic components are chosen.

3. Placing the Insert

The insert is carefully positioned inside the mold.

4. Injecting the Plastic

Molten plastic flows around the insert, bonding to it.

5. Cooling and Solidifying

The part cools and hardens inside the mold.

6. Ejecting the Finished Part

The molded part is removed and inspected.

7. Quality Control

Every part is checked for defects and strength.

Materials Used in Medical Insert Molding

1. Thermoplastics

Used for strong, lightweight medical components.

2. Liquid Silicone Rubber (LSR)

Soft and flexible, ideal for seals and tubing.

3. Polycarbonate (PC)

Impact-resistant, perfect for housings and covers.

4. Stainless Steel Inserts

Adds strength and durability to medical devices.

5. Titanium Inserts

Used in implantable medical products.

Challenges in Medical Insert Molding

1. Insert Placement Accuracy

Even slight misalignment can cause defects.

2. Material Compatibility

Plastic and inserts must bond properly.

3. Sterilization Requirements

Medical parts must withstand sterilization processes.

4. Complex Mold Design

Mold makers need advanced skills to create precise molds.

5. Cost of High-Quality Materials

Medical-grade plastics and metals can be expensive.

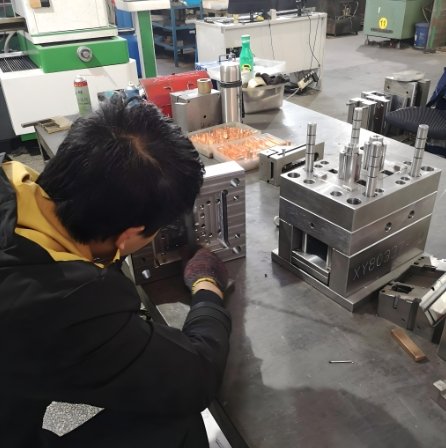

Role of Mold Makers in Insert Molding

1. Designing Custom Molds

They create molds for complex medical devices.

2. Ensuring Precision

Mold makers use advanced techniques for accuracy.

3. Optimizing Production

They improve cycle times and reduce waste.

4. Maintaining Mold Quality

Durable molds ensure consistent results.

Future Trends in Medical Insert Molding

1. Smart Medical Devices

Insert molding integrates sensors for real-time monitoring.

2. Miniaturization

Smaller, more precise parts for medical wearables.

3. Biocompatible Materials

Safer plastics for implantable devices.

4. AI-Driven Quality Control

Artificial intelligence improves defect detection.

Insert molding enhances medical injection molding by improving strength and precision. Mold makers ensure high-quality production. As technology advances, insert molding will continue to transform medical manufacturing.