Medical devices require high-precision manufacturing. Medical injection molding is the best process for mass production. It creates identical parts with strict quality control. Mold makers use advanced technology to meet medical industry demands. This process ensures efficiency, consistency, and cost-effectiveness.

What Is High-Volume Medical Injection Molding?

1. Definition

High-volume injection molding produces thousands to millions of medical parts. It uses automated systems for consistent quality.

2. Why It’s Important

Medical devices must meet strict safety standards. High-volume production ensures accuracy and efficiency. Mold makers design durable molds for long production runs.

3. Key Features

- Fast production cycles.

- High precision and consistency.

- Low per-unit cost.

- Suitable for mass manufacturing.

Materials Used in High-Volume Medical Injection Molding

1. Biocompatible Plastics

- Safe for human contact.

- Used in implants and surgical tools.

2. Liquid Silicone Rubber (LSR)

- Flexible and durable.

- Ideal for seals and tubing.

3. High-Performance Thermoplastics

- Withstand sterilization.

- Used in surgical instruments.

4. Radiopaque Polymers

- Visible in medical imaging.

- Used in catheters and implants.

5. Antimicrobial Plastics

- Reduce bacterial growth.

- Improve hygiene in medical settings.

The High-Volume Injection Molding Process

1. Design and Prototyping

- Engineers design the part.

- Prototypes are tested for function.

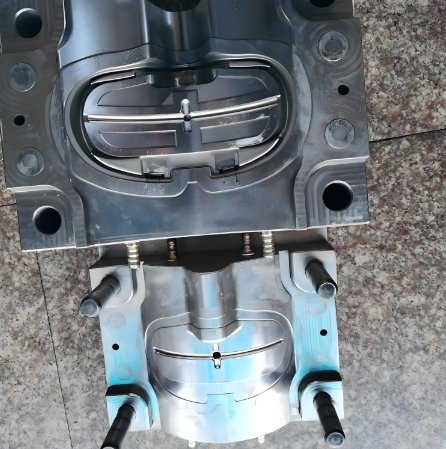

2. Mold Making

- Mold makers create precision molds.

- Molds must withstand high pressure.

3. Material Preparation

- Plastic pellets or liquid silicone are chosen.

- Materials are tested for quality.

4. Injection Molding Process

- Material is heated and injected into the mold.

- The mold shapes the part under high pressure.

- The part cools and solidifies.

5. Ejection and Inspection

- The mold opens and releases the part.

- Parts are inspected for defects.

6. Post-Processing

- Trimming removes excess material.

- Sterilization ensures safety.

Equipment Used in High-Volume Medical Injection Molding

1. Automated Injection Molding Machines

- Operate at high speeds.

- Reduce human error.

2. Multi-Cavity Molds

- Produce multiple parts per cycle.

- Increase efficiency.

3. Hot Runner Systems

- Improve material flow.

- Reduce waste and cycle time.

4. Quality Control Systems

- Inspect parts using sensors.

- Ensure precision and consistency.

5. Cleanroom Facilities

- Prevent contamination.

- Meet medical standards.

Applications of High-Volume Medical Injection Molding

1. Surgical Instruments

- Handles and grips for medical tools.

2. Drug Delivery Devices

- Inhalers, syringes, and auto-injectors.

3. Medical Tubing and Connectors

- Used in IV and fluid management systems.

4. Diagnostic Equipment

- Housings and test cartridges.

5. Implantable Components

- Pacemaker casings and orthopedic implants.

Challenges in High-Volume Medical Injection Molding

1. Strict Regulatory Compliance

- Must meet FDA and ISO standards.

- Requires extensive documentation.

2. Consistency in Mass Production

- Every part must be identical.

- Requires high-precision molds.

3. Material Selection

- Plastics must be biocompatible.

- Must withstand sterilization.

4. High Initial Tooling Costs

- Mold makers design complex molds.

- Requires significant investment.

5. Maintaining Cleanroom Conditions

- Must prevent contamination.

- Requires strict environmental control.

How Mold Makers Ensure Precision in High-Volume Production

1. Advanced Mold Design

- Uses CAD software for accuracy.

- Designs for long-lasting performance.

2. CNC Machining for Molds

- Creates fine details in mold cavities.

- Ensures tight tolerances.

3. Automated Quality Control

- Uses vision systems and sensors.

- Detects defects before production issues occur.

4. Rapid Prototyping and Testing

- Tests molds before mass production.

- Saves time and prevents errors.

Advantages of High-Volume Medical Injection Molding

1. High Efficiency

- Produces thousands of parts per hour.

- Reduces production time.

2. Cost-Effective for Large Orders

- Lowers per-unit costs.

- Ideal for mass manufacturing.

3. Consistent Quality

- Every part meets specifications.

- Reduces product failures.

4. Sterilization Compatibility

- Materials withstand heat and chemicals.

- Safe for medical use.

5. Reduced Material Waste

- Advanced systems minimize scrap.

- Supports sustainability.

Future Trends in High-Volume Medical Injection Molding

1. AI and Automation

- Improves production efficiency.

- Reduces defects.

2. Smart Materials

- Develops self-healing plastics.

- Enhances medical device longevity.

3. Sustainable Bioplastics

- Reduces environmental impact.

- Supports green manufacturing.

4. 3D Printing and Injection Molding

- Combines rapid prototyping with mass production.

- Allows for custom medical devices.

5. Micro Injection Molding

- Creates ultra-small medical components.

- Expands treatment possibilities.

Medical injection molding enables mass production of medical parts. Mold makers ensure precision, efficiency, and compliance. High-volume manufacturing reduces costs and improves patient safety. This process remains essential for modern medical advancements.