The economics of medical injection molding depend on cost control, efficiency, and profitability. Manufacturers must balance material costs, labor, automation, and compliance expenses. Mold makers play a crucial role in optimizing production and reducing waste. Understanding these factors helps businesses remain competitive while ensuring high-quality medical components.

1. Key Cost Factors in Medical Injection Molding

1.1 Material Costs

- Medical-grade plastics are expensive.

- Biocompatible materials meet FDA and ISO standards but increase costs.

- Recycled plastics reduce expenses but may have limitations.

1.2 Mold Design and Tooling Costs

- Mold makers create durable molds, but initial costs are high.

- Multi-cavity molds increase production efficiency.

- Hot runner systems reduce waste but cost more upfront.

1.3 Labor and Workforce Expenses

- Automation reduces labor costs.

- Skilled technicians ensure quality but require higher wages.

- Training programs improve efficiency but add short-term costs.

1.4 Energy Consumption

- Electric injection molding machines use 30% less energy.

- Smart cooling systems lower energy costs.

- Optimized scheduling reduces power usage during peak hours.

1.5 Compliance and Regulatory Costs

- Medical injection molding must meet strict industry standards.

- FDA and ISO audits require documentation and testing.

- Cleanroom production increases operational expenses.

2. Cost-Saving Strategies in Medical Injection Molding

2.1 Material Optimization

- Use lightweight polymers to reduce resin use.

- AI-driven monitoring prevents material waste.

- Recycling excess plastic lowers costs.

2.2 Efficient Mold Design

- Mold makers create long-lasting steel molds.

- Modular molds allow quick design changes.

- Hot runner systems minimize scrap material.

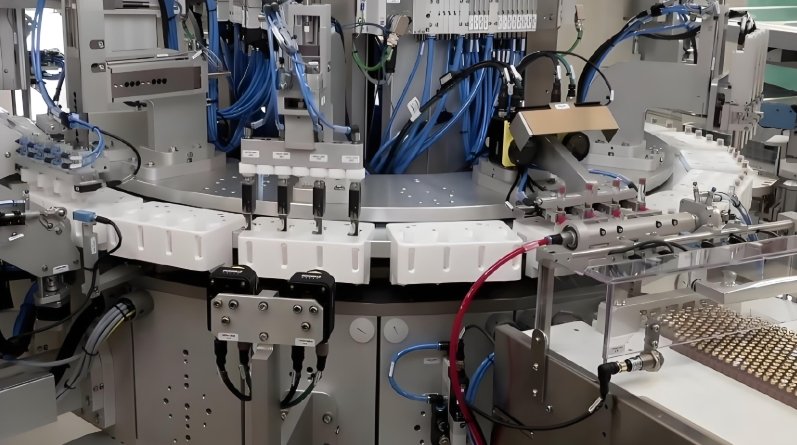

2.3 Automation for Cost Reduction

- Robotics improve cycle times and precision.

- AI-powered quality control prevents defective parts.

- IoT monitoring reduces machine downtime.

2.4 Energy Efficiency Measures

- Smart factory solutions optimize machine power use.

- Hybrid injection molding machines balance speed and energy savings.

- LED lighting and efficient HVAC systems reduce facility costs.

3. How Mold Makers Influence the Economics of Injection Molding

3.1 Designing Cost-Effective Molds

- Mold makers choose materials that extend mold life.

- Durable molds require fewer replacements, lowering long-term costs.

3.2 Enhancing Mold Cooling Systems

- Faster cooling reduces cycle times.

- Reduces energy consumption and increases output.

3.3 Customizing Molds for Multi-Purpose Use

- Modular mold designs adapt to different products.

- Lowers tooling costs by reducing the need for multiple molds.

3.4 Predictive Maintenance for Longevity

- IoT sensors track mold wear in real time.

- Prevents expensive breakdowns and production delays.

4. Profitability in Medical Injection Molding

4.1 High-Volume Production Benefits

- Producing millions of units reduces per-unit cost.

- Fixed costs spread across large production runs.

4.2 Low-Volume Manufacturing Challenges

- Short-run productions require frequent mold changes.

- Increases costs due to setup and downtime.

4.3 Product Differentiation for Competitive Advantage

- Custom medical components attract premium pricing.

- Advanced materials increase product value.

4.4 Supply Chain Optimization for Cost Savings

- Just-in-Time (JIT) inventory lowers storage expenses.

- Bulk purchasing reduces material costs.

5. Challenges in Medical Injection Molding Economics

5.1 Rising Raw Material Costs

- Oil price fluctuations impact plastic resin pricing.

- Sustainable alternatives may reduce long-term dependency.

5.2 Labor Shortages in Skilled Manufacturing

- High demand for technicians increases wages.

- Automation fills labor gaps but requires investment.

5.3 Regulatory Compliance Expenses

- Meeting medical device standards requires extensive documentation.

- Testing and validation increase overall costs.

5.4 Machine Downtime and Production Delays

- Equipment failures disrupt supply chains.

- Predictive maintenance minimizes downtime losses.

6. Innovations Reducing Medical Injection Molding Costs

6.1 AI-Powered Production Optimization

- Machine learning adjusts settings for minimal waste.

- AI detects defects before full production runs.

6.2 Digital Twin Technology for Mold Testing

- Simulates molding processes before production.

- Prevents costly trial-and-error adjustments.

6.3 3D Printing for Prototyping

- Lowers tooling costs for initial product testing.

- Reduces lead time for new mold development.

6.4 Smart Factories with IoT Integration

- Real-time data improves efficiency and reduces energy waste.

- Automated adjustments optimize production in real time.

7. Future Trends in Medical Injection Molding Economics

7.1 Fully Automated Manufacturing Facilities

- AI-driven robots will handle material feeding, molding, and inspection.

- Reduces human labor costs significantly.

7.2 Sustainable and Biodegradable Plastics

- Reduces regulatory risks associated with traditional plastics.

- Meets growing demand for eco-friendly medical devices.

7.3 Blockchain for Supply Chain Transparency

- Tracks raw material costs and prevents pricing manipulation.

- Ensures ethical and cost-effective sourcing.

7.4 On-Demand Injection Molding

- Reduces inventory costs with small-batch, on-demand production.

- Shorter lead times improve market responsiveness.

7.5 AI-Driven Predictive Analytics for Cost Reduction

- AI forecasts material needs to avoid over-purchasing.

- Identifies cost-saving opportunities in machine efficiency.

The economics of medical injection molding depend on material costs, labor, automation, and mold design. Mold makers optimize efficiency, reducing expenses while maintaining quality. AI, IoT, and smart factories further improve cost-effectiveness. By adopting innovative strategies, manufacturers can maximize profitability while ensuring compliance with industry standards.