Making electronic parts takes skill.

You need speed.

You need quality.

You need the right partner.

That partner is your Mold Maker.

In Electronic Injection Molding, not all mold makers are equal.

Picking the wrong one will cost time and money.

The right one brings success.

Why It Matters

Electronics need small parts.

They need perfect shapes.

Tiny errors cause big problems.

Good molds stop defects.

Bad molds create waste.

So, choosing a Mold Maker is the first big step.

Especially in Electronic Injection Molding.

Look for Experience in Electronics

Not all mold makers understand electronics.

That’s a problem.

Ask about past projects.

Have they worked with circuit parts?

Sensors?

Connectors?

In Electronic Injection Molding, details matter.

So, experience matters too.

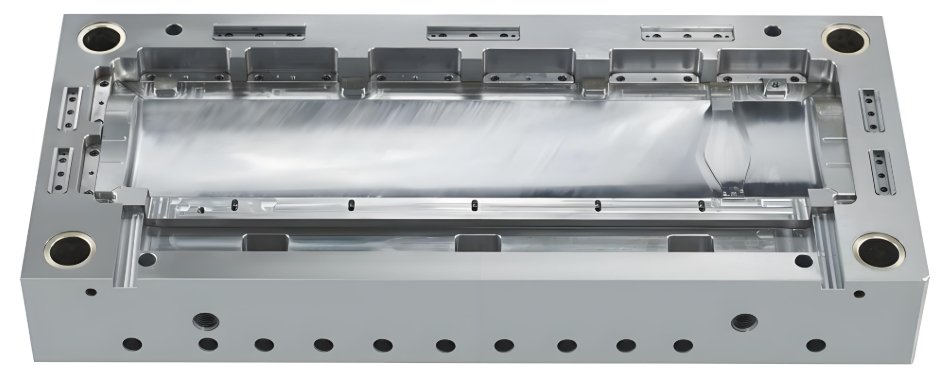

Precision Equipment

Ask what machines they use.

Do they have high-speed CNC?

Wire EDM?

Mirror EDM?

Better tools = better molds.

A skilled Mold Maker uses precise tools.

That’s key for micro-parts.

And tight tolerances.

Use of Mold Flow Analysis

Simulation saves time.

Simulation saves cost.

Does the Mold Maker use Mold Flow software?

If yes, that’s a good sign.

Electronic Injection Molding needs perfect flow.

Analysis helps avoid short shots.

Or warping.

This helps get it right the first time.

Cleanroom Molding Options

Electronic parts can be sensitive.

Dust can ruin them.

A top Mold Maker offers cleanroom solutions.

Especially for:

- Medical electronics

- Sensors

- IC packaging

Ask if they have cleanroom molding setups.

High Cavity and Multi-Cavity Experience

Some parts need volume.

And speed.

Multi-cavity molds do that.

Can the Mold Maker handle those?

Can they balance flow between cavities?

This is vital in Electronic Injection Molding.

More parts.

Less time.

Lower cost.

Knowledge of Plastic Materials

Different parts need different resins.

Some need ESD protection.

Some need heat resistance.

Your Mold Maker must know plastics.

And how they flow.

The wrong material causes big problems.

Quick Prototyping

Speed matters.

Can they make prototypes fast?

3D printed molds?

Aluminum soft tools?

Testing early helps avoid delays.

Good Mold Makers offer this.

Especially for startups.

Or fast-moving markets.

Tool Maintenance and Support

Molds wear out.

Things break.

Ask about after-sales service.

Do they offer repairs?

Polishing?

Adjustments?

A good Mold Maker stands behind their tools.

They keep you running.

Certifications and Standards

Electronics often need certified parts.

ISO 9001 is basic.

IATF 16949 is better.

Some need ISO 13485 for medical devices.

A qualified Mold Maker knows these standards.

They follow strict rules.

That builds trust.

And ensures safety.

Transparent Communication

Projects need teamwork.

Bad communication slows you down.

Pick a Mold Maker who answers fast.

One who shares reports.

One who explains problems clearly.

Especially in Electronic Injection Molding,

small issues can become big.

Location and Delivery Times

Is the Mold Maker local?

Or overseas?

Offshore can save money.

But it can slow delivery.

If time-to-market is critical,

a local Mold Maker might be better.

Ask how fast they deliver.

And how they ship molds or parts.

Check Sample Quality

Always ask for samples.

Look at the details.

Are there burrs?

Is the surface smooth?

Do all parts match in size?

Good Electronic Injection Molding makes clean parts.

No warping.

No flash.

No sink marks.

Let the sample do the talking.

Scalability

Can they grow with you?

Can they make small batches now?

Can they scale to millions later?

The right Mold Maker supports both.

From prototype to mass production.

Strong Engineering Team

Behind every good mold is a good team.

Check the team size.

Ask how many engineers they have.

Do they speak your language?

Good engineers save time.

They solve problems before they grow.

They make Electronic Injection Molding smooth.

Flexible Mold Design Options

Some molds need inserts.

Some need slides.

Some need hot runners.

Your Mold Maker should offer all types.

They should recommend the best for your job.

Not just the one they like.

Flexibility means better results.

Reasonable Cost, Not the Cheapest

Cheap molds cost more later.

Due to repairs.

And poor part quality.

The best Mold Maker offers fair pricing.

Not the lowest.

Not the highest.

Just right.

Look for value.

Not just cost.

Client References

Ask for references.

Call past customers.

Were they happy?

Did the molds last long?

Was service good?

A proven Mold Maker has fans.

Good ones will proudly share reviews.

Industry Specialization

Some Mold Makers focus on automotive.

Some on toys.

Others on electronics.

You want one with Electronic Injection Molding as a core skill.

Not a side project.

Their tools, staff, and systems will match your needs.

Strong Project Management

Good molds need planning.

Does the company follow a timeline?

Do they share weekly progress updates?

Do they manage changes well?

In Electronic Injection Molding, delays hurt.

So choose a Mold Maker who sticks to the plan.

Electronic Injection Molding is serious work.

So is picking the right Mold Maker.

Look for:

- Experience

- Tools

- Speed

- Communication

Don’t rush the choice.

A good Mold Maker saves time.

Reduces scrap.

Delivers perfect parts.

Choose wisely.

And your electronics will work better.

Run longer.

And reach the market faster.

Start with the right mold.

And everything else follows.