The automotive industry relies on parts that are strong, reliable, and cost-effective. From dashboards to fuse box covers, many of these parts are plastic housings. Housing Injection Molding is the process that makes these components quickly and accurately. Behind each molded part is a skilled Mold Maker, who ensures that each housing meets high standards.

In this article, we will explore how Housing Injection Molding works in the automotive industry. We will also look at the important role of the Mold Maker in producing high-performance plastic housing parts.

Why Plastic Housing Matters in Automotives

Modern vehicles contain many plastic components. These parts reduce weight, improve fuel efficiency, and allow more design flexibility. Some common automotive housings include:

- Electronic control unit (ECU) housings

- Sensor covers

- Fuse box casings

- Switch enclosures

- Lighting housings

- HVAC unit covers

Each of these parts protects internal systems from dust, moisture, vibration, and heat. Housing Injection Molding ensures these parts are accurate, repeatable, and cost-efficient.

What Is Housing Injection Molding?

Housing Injection Molding is a process where melted plastic is injected into a mold to form a specific shape. The mold creates the outer shell or housing of a part. Once the plastic cools and hardens, the mold opens, and the part is removed.

The advantages of Housing Injection Molding include:

- High production speed

- Accurate dimensions

- Smooth surface finish

- Low waste

- Support for many plastic types

For the automotive industry, this process is ideal for making lightweight, tough housings that last under extreme conditions.

The Role of the Mold Maker in Automotive Projects

The Mold Maker is the person or team responsible for creating the mold used in the injection process. Without a high-quality mold, even the best machine can’t produce a good part. Automotive parts must meet tight tolerances and function under stress, so the Mold Maker must be skilled and precise.

Steps taken by the Mold Maker:

- Analyze the housing design

- Choose the right mold material (usually hardened steel)

- Machine the core and cavity

- Add cooling lines and ejector pins

- Test and adjust the mold for high-volume production

A good Mold Maker understands how the plastic flows, cools, and shrinks. They plan every detail to avoid warping, short shots, or flash in the finished housing.

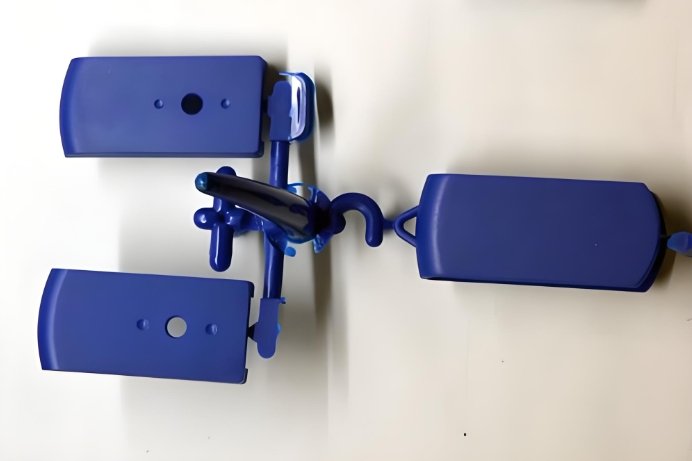

Key Automotive Housing Parts Made with Injection Molding

There are many housing parts in vehicles that are created using Housing Injection Molding. Here are some common examples:

ECU (Electronic Control Unit) Housings

These protect sensitive electronics that control the engine, brakes, and other systems. They must be sealed and resistant to heat and vibration.

Sensor Housings

Modern cars have many sensors for things like air pressure, speed, and temperature. These housings must be small and precise.

Lighting System Housings

Tail lights, headlamps, and indicators all require durable plastic housings that protect bulbs and wires from impact and water.

HVAC System Covers

Heating and cooling units in cars need strong, lightweight housings that can handle temperature changes.

Each of these parts must meet exact standards. Housing Injection Molding helps meet those demands in large volumes. The Mold Maker ensures every feature is molded correctly the first time.

Plastics Used in Automotive Housings

Not all plastics are the same. Automotive parts often require plastics that resist heat, UV rays, chemicals, and impact. Common plastics used include:

- ABS (Acrylonitrile Butadiene Styrene) – Tough and easy to mold

- PC (Polycarbonate) – Very strong and often used in lighting housings

- PA (Nylon) – Used for parts needing extra heat resistance

- PBT (Polybutylene Terephthalate) – Excellent for electrical parts

- PP (Polypropylene) – Lightweight and chemical resistant

A good Mold Maker designs the mold based on the plastic’s flow rate, shrinkage, and required strength. This ensures the final product meets all performance and safety standards.

The Injection Molding Process for Automotive Housing Parts

Let’s walk through how a typical Housing Injection Molding project works from start to finish.

Step 1: Design

The design of the housing part is prepared using CAD software. Engineers and designers ensure the part will fit in the car and perform well under stress.

Step 2: Mold Building

The Mold Maker takes the 3D model and builds the mold. This includes:

- Core and cavity

- Cooling system

- Ejection system

- Proper gating and venting

This stage is very detailed. Even small errors can cause defects in thousands of parts.

Step 3: Molding

Plastic pellets are heated and injected into the mold. Once cooled, the part is ejected. This cycle is repeated many times. A single mold can produce thousands of parts before needing repair.

Step 4: Quality Inspection

Each part is checked for:

- Warping

- Cracks

- Dimensions

- Surface finish

This ensures every piece meets the car maker’s strict quality standards.

Benefits of Housing Injection Molding in the Auto Industry

Using Housing Injection Molding for automotive parts offers several major benefits:

- Consistency: Every part is the same as the last.

- Speed: Large numbers of housings can be made in a short time.

- Design flexibility: Complex shapes, textures, and logos can be added easily.

- Cost savings: Less waste and high efficiency reduce costs.

- Strength and lightness: Ideal for fuel-saving designs.

These benefits make Housing Injection Molding the best choice for many auto components. And a skilled Mold Maker ensures every benefit is delivered properly.

Challenges and How Mold Makers Solve Them

The process is not without challenges. Here are some common ones and how the Mold Maker handles them:

- Warping: Adjusts gate size and cooling rate

- Short shots: Changes injection pressure or adds air vents

- Flash: Improves parting line seal

- Uneven cooling: Adds more cooling channels or changes layout

Each problem requires experience and precision to fix. That’s why having an expert Mold Maker is essential to success.

Real Examples in the Automotive Industry

Automotive brands around the world use Housing Injection Molding. Parts like:

- Control module covers

- Battery pack housings in EVs

- Dash panel inserts

- Mirror casing units

All come from well-designed molds made by skilled Mold Makers. The parts protect, support, and organize systems inside every vehicle.

Housing Injection Molding is the backbone of modern automotive housing production. It delivers the speed, quality, and performance required by today’s car manufacturers. From sensor shells to lighting cases, plastic housings are found in every part of a vehicle.

But none of this works without a reliable Mold Maker. These experts create the tools that shape the plastic. Their knowledge ensures each part is consistent, strong, and ready for the road.

If your project needs durable, high-precision plastic housings, trust Housing Injection Molding—and choose a Mold Maker who understands the demands of the automotive world.