Quick Turnaround Using Housing Injection Molding and Trusted Mold Maker Expertise

Bringing a new plastic housing to market is never simple. It requires speed, accuracy, and careful design. Fast prototyping plays a critical role in reducing risk and cutting time to production. In housing Injection Molding, speed is essential—yet you cannot sacrifice quality. That’s where expert Mold Maker support becomes invaluable.

This article explains how fast prototyping works in housing Injection Molding. We’ll look at key steps, common materials, and how an experienced Mold Maker can reduce delays while ensuring functional, testable parts.

What Is Fast Prototyping in Housing Injection Molding?

Fast prototyping refers to building a small number of sample housings quickly—usually for design testing or early function validation. In the world of housing Injection Molding, this helps companies test physical form, fit, and performance before investing in full-scale molds.

These prototypes may not be the final production parts. But they must mimic the real thing well enough for testing. That’s why you need a capable Mold Maker who understands the balance between speed and accuracy.

Why Fast Prototyping Matters

Speed matters. Especially in industries like electronics, medical, and IoT devices, where time-to-market is everything.

Main benefits of fast prototyping:

- Catch design flaws early

- Test part fitting and assembly

- Prove mechanical strength

- Get investor or market feedback

- Reduce mold rework later

- Speed up product approval

Without prototyping, companies risk building expensive molds that won’t work right. With it, they move ahead confidently, knowing their housing Injection Molding process has been validated.

Options for Fast Prototyping of Housings

There are several ways to prototype plastic housings quickly. Choosing the best method depends on the part’s use, timeline, and budget. Let’s look at the most common techniques supported by your Mold Maker.

1. 3D Printing

This is the fastest method. It doesn’t involve molds and can produce parts in a matter of hours. 3D printing is excellent for evaluating basic shapes, button layouts, and hand-feel.

However, 3D printed housings don’t match final materials, strength, or surface finish. They’re ideal for early design feedback but not for final mechanical testing.

2. CNC Machining

Machined housings are cut from solid plastic blocks. This method is accurate and can simulate production materials better than 3D printing. It’s useful for thermal or structural testing.

Still, CNC machining is slower and more costly for complex shapes. Your Mold Maker might suggest it for early testing when real materials are critical.

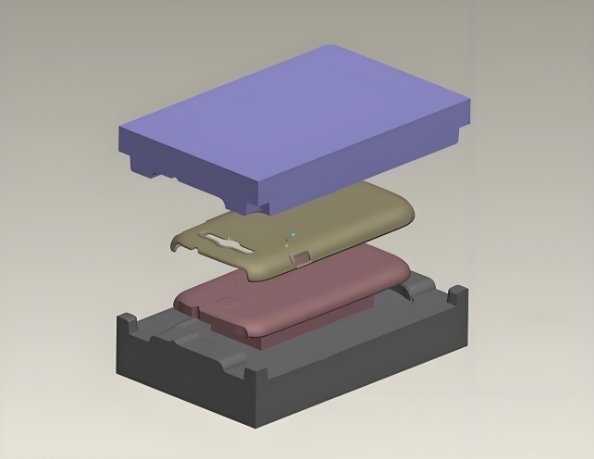

3. Soft Tooling or Prototype Molds

This is the closest you’ll get to real housing Injection Molding. Soft tooling uses aluminum or low-volume steel molds. The molds are quicker and cheaper to make, often within 1–2 weeks.

A skilled Mold Maker can design these molds for short runs—anywhere from 10 to 1,000 parts. This gives you real molded housings, in real production plastic, using the actual injection process.

This is the best method for testing assembly, thermal properties, and high-precision fits.

The Role of the Mold Maker in Fast Prototyping

Your Mold Maker is the key to success in fast prototyping. They guide the entire process, from part design review to mold building and part molding.

How a Mold Maker helps:

- DFM Feedback:

A professional Mold Maker reviews your 3D file and gives advice on wall thickness, draft angles, and undercuts. Fixing these early saves weeks. - Quick Mold Design:

Instead of full production molds, the Mold Maker uses soft or modular tooling designs to save time. - Efficient Gate and Runner Setup:

Proper gate placement improves part flow and finish. Your Mold Maker adjusts it for speed without compromising quality. - Fast Turnaround:

Trusted Mold Maker teams work with rapid processes—often shipping molded samples in under 10 days. - Material Matching:

With experience in housing Injection Molding, your Mold Maker picks plastic that mirrors final performance for early testing.

Materials for Fast Prototyping

You must pick plastics that simulate the final product. Depending on your design goals, your Mold Maker may suggest:

- ABS: Good for fit, surface finish, and moderate strength.

- PC+ABS: Stronger, good for medical and industrial housings.

- Polycarbonate (PC): High impact and heat resistance.

- PP or PE: Flexible for low-stress parts.

Each of these plastics can be processed quickly through soft tooling. And each one supports the goals of early testing in housing Injection Molding projects.

Real-World Example

One client needed a wearable device housing tested in under 2 weeks. They needed to check battery fit, button function, and assembly. Our Mold Maker team used aluminum soft tooling to mold 50 parts in PC+ABS. The parts were shipped in 9 days and passed testing on the first try.

This saved the client from redesigning a final mold—and cut 6 weeks from their project timeline.

From Prototype to Production

Once the prototype parts are tested and approved, the next step is full production. This is where your earlier decisions pay off.

Because your Mold Maker used the same plastic and molding process as the final run, you can now build production tooling with confidence. There’s no guesswork.

And since you’ve proven that your housing Injection Molding process works, the production launch is faster and smoother.

Tips for Faster Prototyping Success

Here are a few practical ways to make your fast prototyping process more efficient:

- Submit clean 3D files with tolerances

- Choose a Mold Maker with experience in low-volume molding

- Be open to material suggestions

- Avoid textures for early molds (polished surfaces are quicker)

- Limit changes once tooling begins

- Approve samples quickly to keep timelines tight

Fast prototyping in housing Injection Molding isn’t just about speed—it’s about building confidence. With a skilled Mold Maker, you get real molded parts, fast. These parts help you test designs, secure funding, and prepare for mass production with fewer risks.

From 3D files to molded samples, a good Mold Maker guides your success. They combine engineering know-how with fast tooling techniques to turn your idea into a real, testable plastic housing—on time and on budget.

If you’re starting a plastic housing project, don’t wait. Work with an expert Mold Maker and accelerate your product launch using proven housing Injection Molding strategies.