When it comes to plastic part production, finding the right partner is crucial. You need precision. You need speed. And most of all, you need a full-service Injection Molding Company that can take your idea from design to delivery—all under one roof. That’s where a trusted Mold Maker comes into play.

In this guide, we’ll explore why working with a full-service Injection Molding Company is the best choice for custom parts. We’ll cover design, mold making, production, and finishing. Every phase is supported by a skilled in-house Mold Maker to guarantee quality and efficiency.

Why Go with a One-Stop Injection Molding Company?

A complete solution saves time and money. When your project stays with one team from start to finish, you avoid delays, miscommunications, and added costs.

A one-stop Injection Molding Company offers:

- In-house mold design and building

- Material selection and testing

- High-volume or low-volume production

- Part design optimization

- Secondary services (assembly, printing, packaging)

- Support from skilled, experienced Mold Maker teams

Having everything in one place creates a smoother workflow and better results.

The Role of the Mold Maker in Custom Projects

The Mold Maker is at the heart of custom part production. They create the tools that shape your ideas into real, physical parts. Precision mold-making determines how your parts will perform, how they will look, and how fast they can be produced.

A skilled Mold Maker ensures:

- Tight tolerances

- Complex geometries

- Optimized cooling and cycle times

- Longer tool life

- Easy maintenance and repair

A good Injection Molding Company invests heavily in its mold-making department because it’s the foundation of quality production.

Step 1: Design and Engineering

The process starts with your concept. You might have a 3D CAD file, a prototype, or just a sketch. A strong Injection Molding Company will work with you to refine the design for manufacturability.

Key services include:

- DFM (Design for Manufacturability) analysis

- Wall thickness optimization

- Gate and runner design

- Parting line and draft considerations

Here’s where your Mold Maker starts preparing mold plans. They think ahead to make sure your mold will work perfectly from day one.

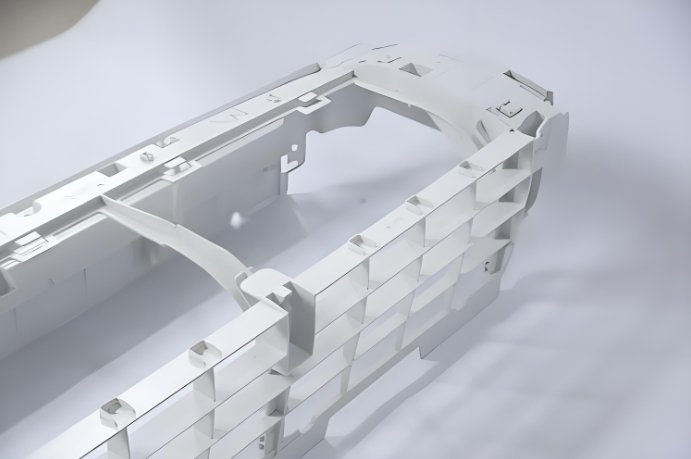

Step 2: Mold Making – The Core of the Process

Once the design is finalized, the mold is built. This step requires precision machining, experience, and high-quality materials. Your Mold Maker uses CNC, EDM, and other advanced tools to create every detail of the mold.

Types of molds a professional Injection Molding Company offers:

- Single-cavity molds

- Multi-cavity molds

- Family molds

- Insert molds

- Hot runner or cold runner systems

The accuracy of the Mold Maker ensures your parts come out right every time.

Step 3: Injection Molding Production

After the mold is complete, it’s installed in the molding press. The machine injects molten plastic into the mold cavity under high pressure. This forms your part with high repeatability.

Your Injection Molding Company will provide:

- Short-run or mass production

- High-speed presses

- Precision molding

- Material flexibility (ABS, PC, nylon, PP, etc.)

- 24/7 production options

Here, quality control systems check for defects. Feedback is shared with the Mold Maker if adjustments are needed.

Step 4: Secondary Operations

Need more than just molded parts? A one-stop Injection Molding Company also offers:

- Pad printing

- Ultrasonic welding

- Heat staking

- Overmolding

- Assembly and packaging

Custom parts often require finishing steps. Having one partner handle it all makes your life easier and ensures consistency.

Materials and Customization Options

The best Injection Molding Company will help you choose the right resin for your project. Your Mold Maker and material team work together to ensure the mold can handle the thermal and flow characteristics of each plastic.

Common materials include:

- ABS (durable, affordable)

- Polycarbonate (impact-resistant)

- Nylon (strong, flexible)

- Polypropylene (lightweight)

- Bioplastics (eco-friendly)

Custom colors, fillers, and additives can also be included.

Applications Across Industries

Custom molded parts are everywhere. A reliable Injection Molding Company serves clients across industries like:

- Automotive

- Medical devices

- Consumer electronics

- Industrial equipment

- Packaging

- Home appliances

No matter your industry, an expert Mold Maker will help you create parts that fit, function, and perform.

Why Customization Requires the Right Team

Custom parts mean custom challenges. Complex shapes. Tight tolerances. Unique performance requirements. You need a Mold Maker who understands your application and can build a mold that delivers top-tier results.

The benefits of working with a complete Injection Molding Company include:

- One project manager from start to finish

- Seamless feedback between design and production

- Faster lead times

- Better quality control

- Lower total project cost

Quality Control and Certification

Look for an Injection Molding Company that follows ISO standards. This ensures your parts are built under a certified process and inspected at every stage.

A reliable company will provide:

- First article inspection (FAI)

- Statistical process control (SPC)

- Dimensional reports

- Material certifications

- Full traceability

Your Mold Maker will also verify tool performance over time, helping you avoid costly surprises later.

Tips for Choosing the Right Partner

When selecting a custom part manufacturer, look for:

- In-house Mold Maker support

- Fast tooling and prototyping

- Flexible production volumes

- Proven track record in your industry

- Positive customer testimonials

- Clear communication and timelines

A strong Injection Molding Company will welcome your questions and help guide your decisions at every stage.

Final Thoughts: One Partner, Complete Control

Custom plastic parts require more than machines—they require skill, experience, and teamwork. Choosing a full-service Injection Molding Company with in-house Mold Maker support gives you better speed, quality, and cost control.

From your first drawing to the final packaged part, your one-stop partner is there to deliver exactly what you need.