In today’s fast-paced manufacturing world, companies need cost-effective ways to produce high-quality plastic housings. Whether for electronics, home appliances, automotive devices, or industrial tools, housing Injection Molding stands out as a top solution. This process combines precision, speed, and affordability. Even better, when you partner with an experienced Mold Maker, the results can meet your technical needs without exceeding your budget.

This article explores how manufacturers achieve affordable housing Injection Molding, the role of the Mold Maker, and how to get the best value without sacrificing quality.

What Is Housing Injection Molding?

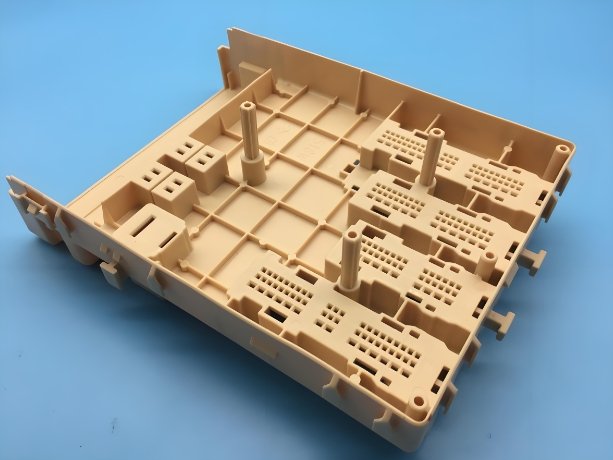

Housing Injection Molding is the process of making protective plastic enclosures using an injection molding machine. Melted plastic is injected into a steel mold. Once cooled, the plastic takes the shape of the mold, forming a strong and accurate housing part.

This method is widely used to produce housings for:

- Smart home devices

- Medical equipment

- Power tools

- Consumer electronics

- Lighting systems

- Car components

Housing Injection Molding is preferred because it allows for high-volume production, consistent quality, and precise shapes—all at a low cost per part.

The Role of a Skilled Mold Maker

The Mold Maker is the expert who designs and builds the mold used in the injection process. A mold is a complex steel tool that shapes the plastic. Its quality directly affects the housing’s strength, look, and function.

An experienced Mold Maker will:

- Choose the right mold steel based on part volume

- Design for proper plastic flow and cooling

- Build molds that reduce cycle times

- Add features like ribs, clips, or screw holes with precision

In affordable housing Injection Molding, the mold is a major investment. That’s why having a professional Mold Maker is key. A well-made mold lasts longer, needs fewer repairs, and produces better parts over time.

How Injection Molding Reduces Costs

There are several reasons why housing Injection Molding is one of the most cost-effective methods for making plastic parts:

1. High Output

Once the mold is ready, the machine can make thousands of housings every day. The more parts you make, the lower the cost per unit becomes.

2. Low Waste

Plastic waste is minimal in injection molding. Excess material can often be reused or recycled.

3. Fast Cycle Times

Modern machines mold a housing in under 60 seconds. With faster cycles, labor and energy costs drop.

4. Automation

Robotic arms, automated feeders, and conveyors reduce human error and speed up production.

5. Long Mold Life

A mold built by a skilled Mold Maker can last hundreds of thousands of cycles. You save money in the long run.

Choosing the Right Material

Material choice affects both price and performance. For affordable housing Injection Molding, common plastics include:

- ABS: Strong, easy to mold, and widely used for electronic housings

- PP (Polypropylene): Lightweight and chemical-resistant

- PC+ABS: Offers strength and good appearance

- HIPS (High Impact Polystyrene): Low-cost and easy to color

- PA (Nylon): For housings that need more strength and heat resistance

An experienced Mold Maker helps match your housing’s function with the right material, balancing price and durability.

What Makes a Molding Company Affordable?

Affordability isn’t just about low prices. It’s about value for your money. A reliable housing Injection Molding company provides:

- Fast quotes and DFM feedback

- Cost-effective mold designs

- Skilled Mold Makers on-site

- In-house tooling to avoid outsourcing

- Short lead times for sampling and mass production

- Good communication and technical support

Factories in China, for example, offer very competitive rates while maintaining high quality. Many Chinese Mold Makers have decades of experience, and the manufacturing facilities run 24/7 to meet global demand.

How to Get Affordable Mold Making

If you want lower prices for your housing Injection Molding project, start by focusing on the mold cost. Here’s how to save:

- Keep part designs simple

Avoid undercuts and unnecessary features unless they are critical. - Use standard mold bases

A good Mold Maker can customize inserts inside a standard mold to reduce cost. - Limit the number of cavities

Fewer cavities mean lower initial mold costs, though it may affect speed. - Choose the right steel

For lower-volume runs, softer steel like P20 works well and costs less. - Plan ahead for part volume

A mold built for 10,000 parts should not be overbuilt. Save money by matching the mold to your expected production.

Real-World Applications

Affordable housing Injection Molding is helping startups and global brands alike. Some examples:

Smart Home Products

Thermostats, door sensors, and light controllers use sleek plastic housings. Molding keeps the design smooth and the cost low.

Power Banks and Battery Packs

Plastic enclosures for power storage need strong clips and tight tolerances. A good Mold Maker ensures long-term use.

Remote Controls and Gadgets

Consumer electronics need plastic casings that are both affordable and attractive. Injection molding does both.

LED Light Fixtures

Plastic housings for lights must resist heat and provide good appearance. With the right material and mold, this is easy and cost-efficient.

The Step-by-Step Process

Here’s how a typical affordable housing Injection Molding project works:

- Send Your Design

You provide a 3D file and part details. - Design for Manufacturing (DFM)

The Mold Maker checks your design and suggests improvements. - Mold Quotation

You get prices for the mold and parts, with estimated timelines. - Mold Building

Once approved, the mold is made and tested. - T1 Samples

You receive first-run samples to check fit and finish. - Part Approval

If needed, minor changes are made. - Mass Production

Once approved, full production begins. - Packing and Delivery

Parts are shipped securely and on time.

This smooth process ensures your housing Injection Molding project stays within budget and meets your timeline.

Cost-effective plastic housings are possible when you combine smart design, the right material, and an experienced Mold Maker. Housing Injection Molding offers unbeatable value by reducing per-part costs, improving quality, and speeding up production.

By choosing the right factory and working with expert Mold Makers, you can get affordable solutions without lowering your standards. Whether you’re a startup making your first prototype or a manufacturer producing thousands of units, affordable housing Injection Molding is the key to product success.

Trust in professionals who understand every detail of mold making and plastic flow. Let them guide your project to a cost-effective finish—on time, on spec, and within your budget.