Speeding Up Time-to-Market with Efficient Injection Molding

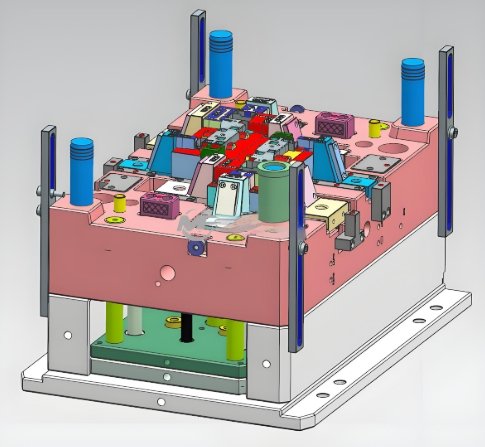

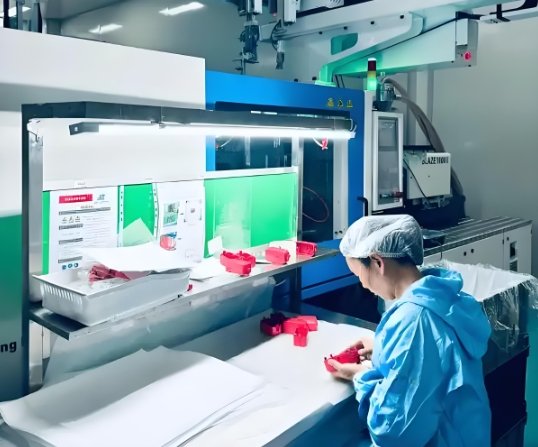

Speed matters.Markets move fast.You must move faster.Electronic Injection Molding helps.A skilled Mold Maker makes it even better.Let’s see how to shorten product launch times. Fast Design to Tooling Use 3D Prototypes First Quick 3D models test ideas fast.No waiting for tooling.Catch design errors early.Electronic Injection Molding benefits from solid prep. Digital Mold Design Use CAD […]

Speeding Up Time-to-Market with Efficient Injection Molding Read More »