Overmolding in Electronics: Benefits and Techniques

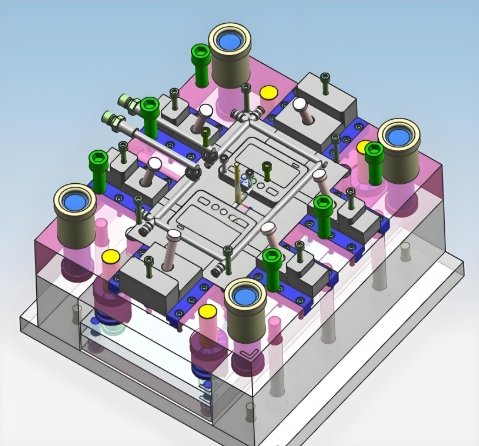

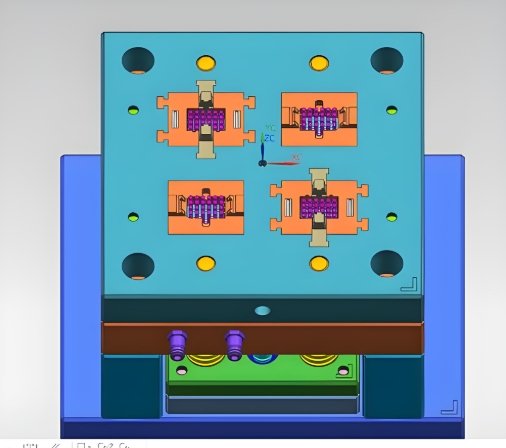

Overmolding is a critical process in electronic injection molding. It enhances durability, protection, and functionality. This method involves molding one material over another to create a single, strong component. Mold makers use overmolding to improve electronic parts, ensuring better performance and longevity. This article explores overmolding techniques, materials, benefits, and applications in electronic manufacturing. 1. […]

Overmolding in Electronics: Benefits and Techniques Read More »