Solving Tolerance Issues in Plastic Housing Molding

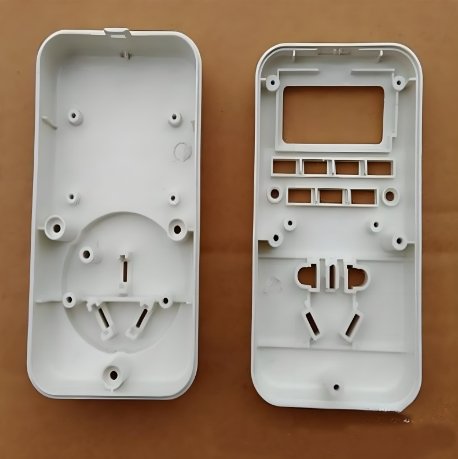

In the world of housing injection molding, precision is everything. Tight tolerances are not just a luxury—they are a necessity. Whether it’s for electronic enclosures, automotive components, or consumer devices, the parts must fit perfectly. However, maintaining those tolerances isn’t always easy. Even small errors can lead to product failures, assembly problems, and costly rework. […]

Solving Tolerance Issues in Plastic Housing Molding Read More »