Key Considerations for Injection Molding Large Parts

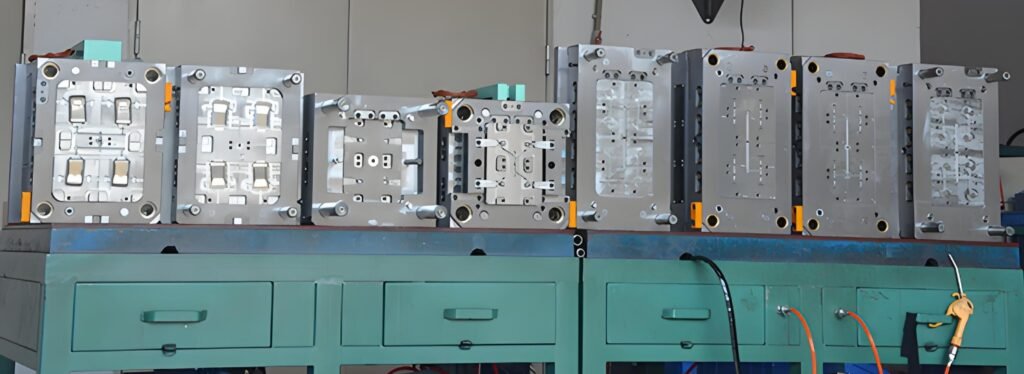

Injection molding is a versatile process used in many industries. For large parts, it presents unique challenges. These challenges require careful planning and adjustments to both design and machinery. Injection molds for large parts must be strong and durable. Mold makers work closely with clients to ensure the parts meet specifications. Material Selection Choosing the […]

Key Considerations for Injection Molding Large Parts Read More »